The electric bicycle industry is experiencing its most significant technological transformation since the introduction of lithium-ion batteries, with 2025 emerging as the pivotal year when integrated gearbox systems, belt drive technology, and automatic shifting converged to create a new paradigm in e-bike design and functionality. This revolution extends far beyond incremental improvements, representing a fundamental reimagining of how electric bicycles operate, maintain themselves, and integrate with riders’ daily lives.

The convergence of these technologies at Eurobike 2025 demonstrated that the industry has reached a maturity point where sophisticated engineering solutions are becoming accessible to mainstream consumers. The integration of compact motors with advanced transmission systems, combined with intelligent software that provides seamless automatic gear shifting based on rider cadence, is creating e-bikes that offer unprecedented simplicity and performance.

This technological evolution addresses long-standing challenges in the e-bike industry, including maintenance complexity, component durability, and user experience optimization. As these innovations move from prototype to production, they promise to transform not only how e-bikes function but also how they integrate into transportation systems, recreational activities, and daily commuting routines.

The Evolution of E-bike Drive Systems

The development of e-bike drive systems has followed a trajectory of increasing sophistication and integration, with 2025 marking a significant acceleration in technological advancement. Modern e-bike drive systems represent the culmination of decades of research in electric motor technology, battery chemistry, and mechanical engineering, creating solutions that were unimaginable just a few years ago.

The fundamental architecture of e-bike drive systems has evolved from simple motor-assist configurations to highly integrated systems that combine propulsion, transmission, and control functions within compact, efficient packages. This evolution has been driven by advances in motor technology that have enabled higher torque outputs from smaller, lighter units while maintaining or improving energy efficiency.

Battery technology improvements have played a crucial role in enabling more sophisticated drive systems, with energy-dense battery packs providing the power necessary to support advanced features like automatic shifting and integrated transmission systems. The relationship between battery capacity, motor efficiency, and system integration has become increasingly optimized, enabling e-bikes that can support complex functionality without compromising range or performance [1].

The integration of sensors, processors, and software into e-bike drive systems has enabled intelligent functionality that was previously impossible. Modern systems can monitor rider input, terrain conditions, and performance parameters in real-time, making automatic adjustments to optimize efficiency, comfort, and performance. This intelligence extends to predictive capabilities that can anticipate rider needs and adjust system behavior accordingly.

The mechanical integration of motors with transmission systems represents one of the most significant recent developments in e-bike technology. By combining these traditionally separate systems, manufacturers can create more compact, efficient, and reliable drive units that offer superior performance while reducing maintenance requirements and improving overall system integration.

Gearbox Integration and Automatic Shifting Technology

The integration of gearbox technology with e-bike drive systems represents a fundamental shift in how electric bicycles manage power delivery and rider input. Traditional e-bike systems rely on external derailleurs and cassettes for gear changes, creating complexity and maintenance challenges that integrated gearbox systems are designed to eliminate.

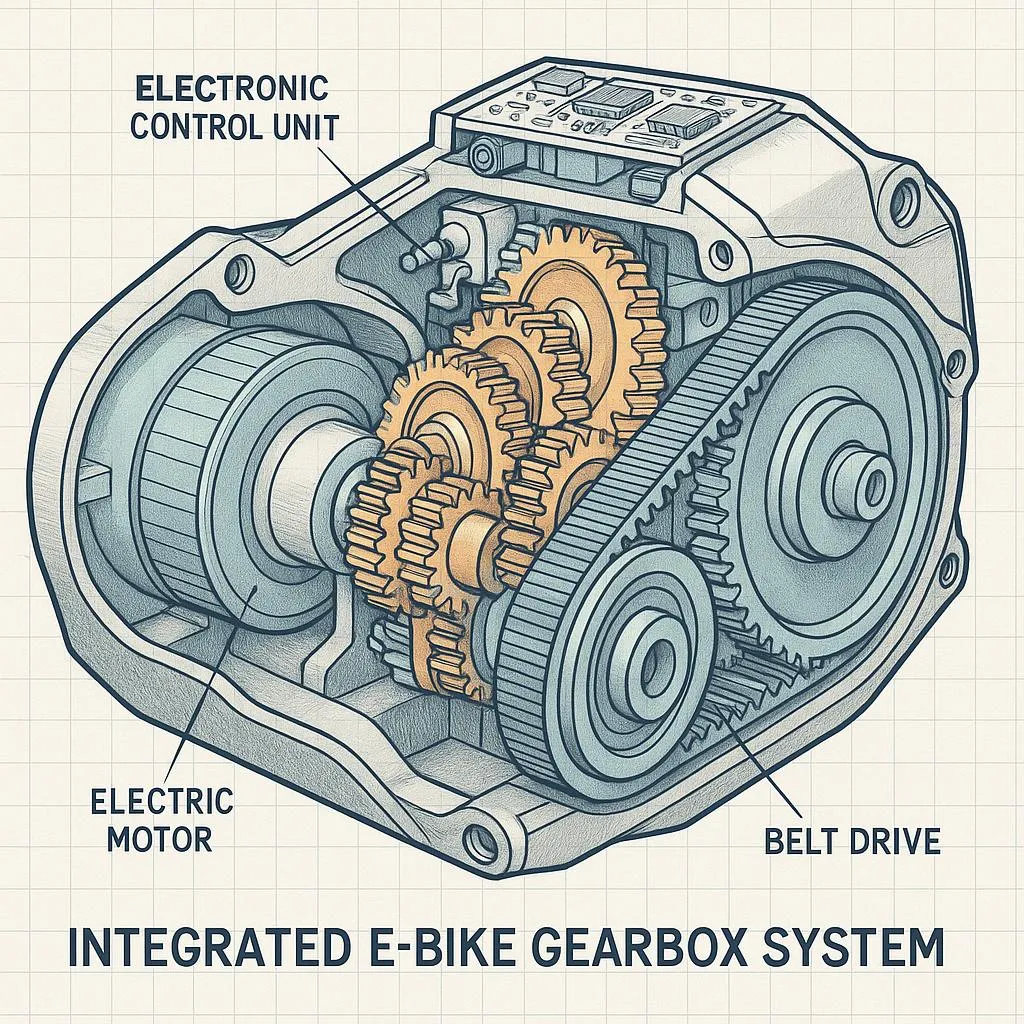

Modern integrated gearbox systems combine the motor, transmission, and control electronics within a single housing, creating a sealed unit that protects internal components from environmental contamination while providing precise, reliable gear changes. This integration enables automatic shifting functionality that responds to rider cadence, power output, and terrain conditions without requiring manual intervention.

The Owuru Drive system exemplifies this integration approach, utilizing infinitely variable transmission technology that provides seamless power delivery without discrete gear steps. This stepless approach eliminates the jarring transitions associated with traditional gear changes, creating a smooth, natural riding experience that adapts continuously to changing conditions [1].

The software systems that control automatic shifting have become increasingly sophisticated, incorporating machine learning algorithms that adapt to individual rider preferences and riding styles. These systems can learn from rider behavior patterns and adjust shifting strategies to optimize comfort, efficiency, and performance based on specific use cases and preferences.

The mechanical advantages of integrated gearbox systems extend beyond automatic shifting to include improved durability, reduced maintenance requirements, and better protection from environmental factors. By enclosing the transmission within the motor housing, these systems eliminate exposure to dirt, moisture, and debris that can compromise traditional derailleur systems.

The integration of gearbox technology with e-bike motors also enables more sophisticated power management strategies, allowing the system to optimize motor output and transmission ratios simultaneously for maximum efficiency. This coordination between propulsion and transmission systems creates opportunities for energy savings and performance improvements that are impossible with separate systems.

Belt Drive Technology and Maintenance Revolution

The adoption of belt drive technology in e-bike applications represents a significant advancement in drivetrain reliability, maintenance reduction, and overall system integration. Belt drives offer fundamental advantages over traditional chain systems, including reduced maintenance requirements, improved durability, and quieter operation that make them particularly well-suited for e-bike applications.

The entry of established manufacturers like Hutchinson into the belt drive market signals the maturation of this technology and its growing acceptance within the cycling industry. Hutchinson’s 135-year history in tire manufacturing brings significant materials science expertise to belt drive development, potentially accelerating innovation and improving product quality [1].

The technical differences between belt drive systems, such as the design variations between Hutchinson and Gates approaches, demonstrate the ongoing innovation in this space. Hutchinson’s approach of using a rib in the center of the belt rather than a cut represents a different engineering philosophy that may offer advantages in strength and durability while requiring different chainring and cog designs.

The compatibility considerations between different belt drive systems highlight both the opportunities and challenges in this evolving market. While the lack of cross-compatibility between systems may initially limit consumer choice, it also drives innovation as manufacturers compete to develop superior solutions and establish market position.

The integration of belt drive technology with automatic transmission systems creates particularly compelling advantages for e-bike applications. The combination eliminates both the maintenance requirements of chain systems and the complexity of manual shifting, creating truly low-maintenance drivetrain solutions that are ideal for commuting and utility cycling applications.

The durability advantages of belt drive systems become particularly important in e-bike applications where higher torque loads and more frequent use can accelerate wear on traditional chain systems. Belt drives can handle these demanding conditions while maintaining consistent performance over extended periods, reducing total cost of ownership and improving user satisfaction.

Market Impact and Consumer Adoption Patterns

The introduction of advanced gearbox and belt drive technologies is reshaping the e-bike market in fundamental ways, creating new product categories and changing consumer expectations about what electric bicycles can offer. The market impact extends beyond technical improvements to influence purchasing decisions, usage patterns, and the overall perception of e-bikes as transportation solutions.

Consumer adoption of these advanced technologies is being driven by the promise of reduced maintenance, improved reliability, and enhanced user experience. The “set-and-forget” functionality offered by automatic shifting systems appeals particularly to commuters and utility cyclists who prioritize convenience and reliability over technical complexity or customization options.

The premium pricing associated with advanced gearbox and belt drive systems initially limits adoption to high-end market segments, but the technology trajectory suggests that costs will decrease as production volumes increase and manufacturing processes mature. This pattern follows the typical adoption curve for cycling technologies, with early adopters paying premium prices for cutting-edge features that eventually become mainstream.

The integration of these technologies with advanced cycling technology trends creates synergies that enhance the overall value proposition of modern e-bikes. The combination of intelligent drive systems with other smart features creates comprehensive solutions that address multiple user needs within integrated platforms.

The impact on traditional bicycle retail and service models is significant, as these advanced systems require different expertise and equipment for service and support. This shift is driving changes in dealer training, service capabilities, and the overall structure of the bicycle retail industry.

The environmental implications of reduced maintenance requirements and improved durability align with sustainable cycling trends, creating additional value for environmentally conscious consumers. The longer service life and reduced consumable requirements of belt drive systems contribute to lower environmental impact over the product lifecycle.

Integration with Urban Mobility and Commuting

The advanced technologies emerging in e-bike design are particularly well-suited for urban mobility and commuting applications, where reliability, low maintenance, and ease of use are paramount considerations. The integration of automatic shifting and belt drive systems addresses many of the barriers that have historically limited e-bike adoption for daily transportation use.

The seamless operation of automatic transmission systems eliminates the need for riders to understand gear selection strategies or manage shifting during stop-and-go urban riding. This simplification makes e-bikes more accessible to riders who may be intimidated by traditional bicycle drivetrains or who simply prefer to focus on navigation and traffic awareness rather than mechanical operation.

The reduced maintenance requirements of belt drive systems are particularly valuable for commuters who rely on their e-bikes for daily transportation and cannot afford unexpected mechanical issues or frequent service requirements. The sealed, low-maintenance nature of these systems provides the reliability that transportation users demand.

The integration of these technologies with urban cycling revolution trends creates opportunities for e-bikes to play larger roles in urban transportation systems. The improved reliability and reduced complexity make e-bikes more suitable for bike-sharing programs, fleet applications, and other institutional uses where maintenance efficiency is critical.

The quiet operation of belt drive systems contributes to the social acceptance of e-bikes in urban environments, reducing noise pollution and making e-bikes more compatible with pedestrian areas and mixed-use spaces. This acoustic advantage supports the integration of e-bikes into urban planning and transportation policy frameworks.

The weather resistance and durability of integrated gearbox systems make e-bikes more suitable for year-round commuting in challenging climates, expanding the potential user base and increasing the transportation utility of electric bicycles. This capability supports the development of e-bike infrastructure and policy frameworks that treat e-bikes as serious transportation alternatives.

Performance Optimization and Efficiency Gains

The integration of advanced gearbox and belt drive technologies enables new levels of performance optimization and efficiency that were previously impossible with traditional e-bike drivetrains. The coordination between motor control, transmission management, and rider input creates opportunities for system-level optimization that maximizes both performance and energy efficiency.

The infinitely variable transmission capabilities of systems like the Owuru Drive enable precise optimization of the relationship between motor speed, wheel speed, and rider cadence. This optimization can be continuously adjusted based on riding conditions, battery state, and performance objectives to maximize efficiency and extend range.

The reduced friction losses associated with belt drive systems contribute directly to improved efficiency and extended battery life. The elimination of chain friction, derailleur drag, and other mechanical losses in traditional drivetrains can provide measurable improvements in overall system efficiency, particularly important for maximizing e-bike range.

The integration of performance optimization with cycling performance and health optimization approaches creates opportunities for e-bikes to support fitness and training goals while providing transportation utility. The ability to precisely control resistance and power delivery enables e-bikes to function as training tools as well as transportation devices.

The data collection capabilities of intelligent drive systems provide valuable feedback for performance analysis and optimization. The integration of sensors and processors enables detailed monitoring of power delivery, efficiency metrics, and rider performance that can inform training decisions and system optimization strategies.

The predictive capabilities of advanced drive systems enable proactive optimization based on route planning, battery state, and rider preferences. These systems can adjust power delivery and transmission strategies to optimize for specific objectives such as maximum range, minimum travel time, or optimal rider comfort.

Manufacturing and Supply Chain Implications

The development and production of advanced gearbox and belt drive systems require significant changes in manufacturing processes, supply chain management, and quality control procedures. The complexity and precision required for these integrated systems demand new approaches to production and assembly that differ significantly from traditional bicycle manufacturing.

The integration of multiple subsystems within compact housings requires advanced manufacturing techniques including precision machining, electronic assembly, and sophisticated testing procedures. The quality control requirements for these systems exceed those of traditional bicycle components, necessitating investment in new testing equipment and procedures.

The supply chain implications of these advanced systems include the need for specialized components, materials, and manufacturing capabilities that may not be readily available within traditional bicycle industry supply networks.