The cycling industry has witnessed a remarkable technological renaissance in 2025, marked by a fundamental shift in how manufacturers and riders approach the eternal balance between weight and aerodynamics. What emerged from the 2025 Tour de France and Eurobike has been nothing short of revolutionary: a new generation of cycling technology that refuses to compromise between lightweight performance and aerodynamic efficiency.

This breakthrough represents the culmination of decades of materials science research, computational fluid dynamics advancement, and real-world testing at the highest levels of professional cycling. The traditional paradigm of choosing between lightweight climbing bikes and aerodynamic time trial machines has been shattered, replaced by sophisticated “do-it-all” designs that excel across the entire spectrum of cycling disciplines.

The implications of this technological revolution extend far beyond professional racing, trickling down to recreational cyclists who can now access performance benefits that were previously reserved for elite athletes. The democratization of advanced cycling technology has created opportunities for riders at every level to experience significant performance improvements without the complexity and expense of maintaining multiple specialized bikes.

The Do-It-All Aero Bike Revolution

The most significant development in cycling technology for 2025 has been the emergence of do-it-all aero bikes that have fundamentally changed how professional teams approach equipment selection. Gone are the days when teams needed separate climbing bikes, aero bikes, and time trial machines for different stages and conditions. The new generation of aero bikes delivers exceptional performance across all disciplines while maintaining the versatility needed for varied racing conditions.

This technological breakthrough was most prominently displayed during the 2025 Tour de France, where multiple teams abandoned their traditional three-bike strategies in favor of single aero platforms that could handle everything from mountain stages to flat sprints to individual time trials. The weight penalties that previously made aero bikes impractical for climbing have been virtually eliminated through advanced materials and innovative design approaches.

The aerodynamic efficiency of these new bikes has reached unprecedented levels, with some models showing drag reductions of 15-20% compared to traditional road bikes while weighing less than 7 kilograms in race-ready configuration. This achievement has been made possible through the integration of computational fluid dynamics modeling with advanced carbon fiber manufacturing techniques that allow for complex shapes and internal routing without weight penalties.

The versatility of do-it-all aero bikes extends beyond just aerodynamics and weight. These bikes incorporate adjustable geometry systems that allow riders to optimize their position for different types of riding, from aggressive time trial positions to more comfortable endurance geometries. This adaptability means that a single bike can serve multiple roles without compromising performance in any specific application.

The integration of electronic shifting systems with these aero platforms has reached new levels of sophistication, with wireless systems that eliminate cable routing complexity while providing instantaneous, precise shifting under all conditions. The reliability and performance of these systems have improved to the point where mechanical shifting is becoming increasingly rare in professional racing.

Advanced Materials and Manufacturing Innovations

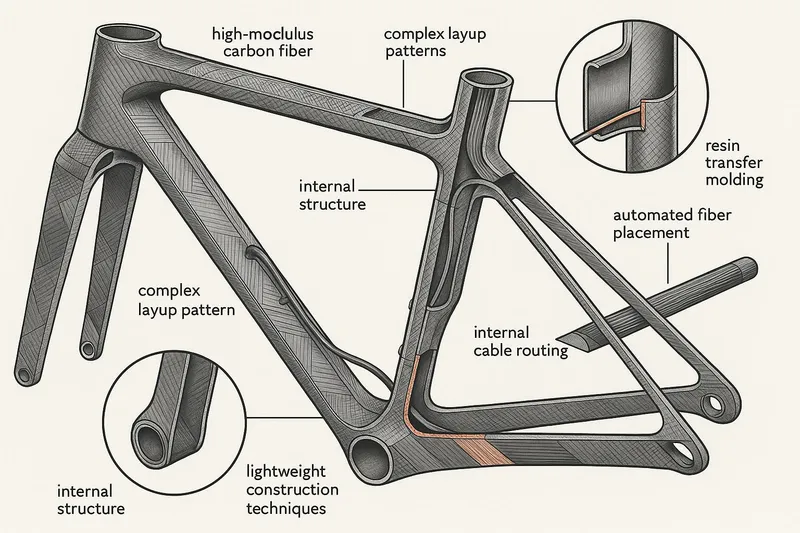

The lightweight aero revolution has been enabled by breakthrough advances in materials science and manufacturing techniques that have fundamentally changed what’s possible in bicycle construction. The development of next-generation carbon fiber composites has allowed manufacturers to create structures that are simultaneously lighter, stronger, and more aerodynamically efficient than ever before.

High-modulus carbon fiber technology has evolved to the point where frame weights below 800 grams are becoming commonplace in high-end bikes, while maintaining the stiffness and durability required for professional racing. These weight reductions have been achieved without compromising structural integrity, with many of the lightest frames actually showing improved fatigue resistance compared to heavier predecessors.

The integration of advanced manufacturing techniques like automated fiber placement and resin transfer molding has enabled the creation of complex internal structures that optimize both weight and aerodynamics. These techniques allow for precise control of fiber orientation and resin distribution, resulting in frames that are optimized for specific load paths and performance characteristics.

Titanium and advanced aluminum alloys have also seen significant development, with new alloys offering strength-to-weight ratios that approach carbon fiber while providing different ride characteristics and durability benefits. These materials are finding applications in high-performance bikes where the unique properties of metal construction provide advantages over carbon fiber.

The development of hybrid construction techniques that combine multiple materials in single components has opened new possibilities for optimization. These approaches allow engineers to place the right material in the right location for optimal performance, creating components that leverage the best characteristics of different materials.

Aerodynamic Design Breakthroughs

The aerodynamic design of cycling equipment has reached new levels of sophistication in 2025, with advances in computational fluid dynamics and wind tunnel testing enabling the creation of shapes and configurations that were previously impossible to develop or validate. The integration of real-world testing with advanced simulation has created a feedback loop that accelerates innovation and improves the accuracy of aerodynamic predictions.

Tube shaping has evolved beyond simple airfoil profiles to incorporate complex three-dimensional shapes that optimize airflow around the entire bike and rider system. These shapes are designed using advanced algorithms that consider the interaction between different components and the effect of rider position on overall aerodynamic performance.

The development of integrated cockpit systems has eliminated many of the aerodynamic penalties associated with traditional handlebar and stem combinations. These integrated systems route cables internally while providing optimal hand positions and aerodynamic profiles that can reduce drag by significant amounts compared to traditional setups.

Wheel aerodynamics has seen dramatic improvements, with new rim profiles and spoke designs that reduce drag while maintaining excellent crosswind stability. The integration of computational fluid dynamics with real-world testing has enabled the development of wheels that perform well across a wide range of wind conditions and yaw angles.

The optimization of component integration has become increasingly sophisticated, with manufacturers designing complete bike systems where every component is optimized to work together aerodynamically. This systems approach has yielded performance benefits that exceed the sum of individual component improvements.

Professional Racing Technology Adoption

The 2025 professional racing season has served as a proving ground for advanced cycling technology, with innovations developed for elite competition quickly finding their way into consumer products. The rapid technology transfer from professional racing to consumer markets has accelerated dramatically, with some innovations appearing in consumer bikes within months of their professional debut.

The adoption of advanced aerodynamic helmets in professional racing has been one of the most visible technology trends of 2025. These helmets, which were once reserved for time trials, are now commonly used in road stages where their aerodynamic benefits outweigh any ventilation compromises. The improved ventilation design of modern aero helmets has made them practical for extended use in varied conditions.

Kit optimization has reached new levels of sophistication, with professional teams employing advanced testing and analysis to optimize every aspect of rider equipment. This includes everything from the aerodynamic properties of different fabric textures to the optimal placement of sponsor logos to minimize drag. The attention to detail in professional kit optimization has revealed performance gains that were previously overlooked.

The use of advanced data analysis in professional racing has enabled teams to make real-time equipment decisions based on course conditions, weather, and tactical considerations. This data-driven approach to equipment selection has proven that the right equipment choices can provide measurable performance advantages in competitive situations.

The integration of power measurement technology with aerodynamic testing has enabled professional teams to quantify the real-world benefits of different equipment choices. This quantitative approach has validated many aerodynamic improvements and identified others that provide minimal benefit in actual racing conditions.

Weight Reduction Techniques and Innovations

The pursuit of weight reduction in cycling equipment has reached new levels of sophistication in 2025, with manufacturers employing advanced techniques and materials to eliminate every unnecessary gram without compromising performance or durability. The weight reduction efforts have extended beyond just frame construction to include every component and accessory on the bike.

Advanced manufacturing techniques have enabled the creation of components with complex internal structures that maintain strength while eliminating material in non-critical areas. These techniques include additive manufacturing, advanced machining, and innovative joining methods that reduce weight while maintaining or improving performance characteristics.

The development of ultra-lightweight components has been balanced with durability considerations, ensuring that weight reduction doesn’t come at the expense of reliability or longevity. Advanced testing protocols and materials analysis have enabled manufacturers to identify the optimal balance between weight, strength, and durability for different applications.

Component integration has become a key strategy for weight reduction, with manufacturers combining multiple functions into single components to eliminate redundant materials and fasteners. This approach has yielded significant weight savings while often improving performance and aesthetics.

The optimization of component sizing and specification has enabled further weight reductions through the use of appropriately sized components for specific applications. This includes everything from using smaller chainrings for specific gear ratios to optimizing cable lengths for specific frame sizes.

Technology Democratization and Accessibility

One of the most significant aspects of the 2025 cycling technology revolution has been the rapid democratization of advanced features that were previously available only to professional athletes or wealthy enthusiasts. The trickle-down effect from professional racing has accelerated dramatically, making cutting-edge technology accessible to a much broader range of cyclists.

Manufacturing scale and efficiency improvements have enabled the production of advanced cycling technology at price points that make it accessible to serious recreational cyclists. The economies of scale achieved through increased production volumes have driven down costs while maintaining quality and performance standards.

The development of technology platforms that can be adapted for different price points has enabled manufacturers to offer advanced features across a range of products. This approach allows cyclists to access key performance benefits without paying for premium features they may not need or want.

The integration of advanced technology into entry-level and mid-range products has raised the performance baseline for all cycling equipment. Features that were once exclusive to high-end products are now standard across most product lines, providing better performance and value for cyclists at every level.

Future Implications and Continuing Innovation

The technological breakthroughs of 2025 represent just the beginning of a new era in cycling innovation. The foundation laid by current advances in materials, aerodynamics, and manufacturing will enable even more dramatic improvements in the coming years.

The integration of artificial intelligence and machine learning into bike design and optimization promises to accelerate innovation and enable the creation of truly personalized cycling equipment. These technologies will allow for the optimization of bike geometry, component selection, and setup for individual riders and specific use cases.

The development of smart materials that can adapt their properties based on conditions or rider input represents another frontier for cycling innovation. These materials could enable bikes that automatically optimize their characteristics for different riding conditions or performance requirements.

The continued advancement of manufacturing technology will enable even more sophisticated designs and further weight reductions while maintaining or improving performance and durability. The integration of new manufacturing techniques with advanced materials will open possibilities that are currently impossible to achieve.

As we look toward the future of cycling technology, it’s clear that the innovations of 2025 have established a new baseline for performance and capability. The lightweight aero revolution has proven that the traditional compromises between different performance characteristics are no longer necessary, opening the door for cycling equipment that excels across all dimensions of performance.

For cyclists looking to benefit from these technological advances, the key is to understand how different innovations align with their specific needs and riding style. The democratization of advanced technology means that significant performance benefits are now accessible to cyclists at every level, making it an exciting time to be involved in the sport of cycling.

The lightweight aero revolution of 2025 represents more than just incremental improvement; it’s a fundamental shift in what’s possible in cycling technology. As these innovations continue to evolve and become more accessible, they promise to enhance the cycling experience for riders around the world, making the sport faster, more efficient, and more enjoyable than ever before.