The cycling industry stands at a pivotal moment in 2025, where environmental consciousness has evolved from a niche concern to a driving force reshaping every aspect of bicycle manufacturing. What began as isolated experiments with alternative materials has blossomed into a comprehensive revolution that’s fundamentally transforming how bicycles are conceived, designed, and produced. This sustainable manufacturing revolution represents more than just an environmental trend—it’s a complete reimagining of the cycling industry’s relationship with our planet.

The urgency driving this transformation cannot be overstated. With global carbon emissions reaching critical levels and consumers increasingly demanding environmentally responsible products, the cycling industry has responded with unprecedented innovation in sustainable manufacturing processes. From bamboo frames that sequester carbon during growth to revolutionary recycling programs that give new life to discarded bicycles, manufacturers are proving that high-performance cycling equipment and environmental stewardship are not mutually exclusive goals.

This revolution extends far beyond simple material substitutions. It encompasses a holistic approach to manufacturing that considers the entire lifecycle of a bicycle, from raw material extraction through end-of-life disposal. Advanced manufacturing techniques are reducing energy consumption by up to 40% compared to traditional methods, while innovative material science is creating components that are simultaneously lighter, stronger, and more environmentally friendly than their conventional counterparts.

The economic implications of this shift are equally profound. Companies embracing sustainable manufacturing are discovering that environmental responsibility often translates directly into cost savings through improved efficiency, reduced waste, and enhanced brand value. Consumer research indicates that 73% of cyclists are willing to pay premium prices for sustainably manufactured bicycles, creating a powerful market incentive for continued innovation in this space.

The Materials Revolution: Beyond Traditional Manufacturing

The foundation of sustainable cycling manufacturing lies in a complete reimagining of the materials used to construct bicycles. Traditional manufacturing has long relied on energy-intensive processes to produce aluminum and carbon fiber components, but 2025 has witnessed an explosion of alternative materials that challenge these conventional approaches while delivering superior performance characteristics.

Bamboo has emerged as perhaps the most revolutionary material in sustainable bicycle manufacturing. Unlike traditional materials that require energy-intensive extraction and processing, bamboo grows rapidly and actually sequesters carbon dioxide during its growth cycle. Advanced bamboo processing techniques developed in 2025 have overcome previous limitations in strength and durability, with modern bamboo frames demonstrating tensile strength comparable to steel while weighing significantly less. The natural vibration-damping properties of bamboo create an exceptionally smooth ride quality that many cyclists prefer over traditional materials.

The bamboo manufacturing process itself represents a masterclass in sustainable production. Harvesting bamboo doesn’t kill the plant, allowing for continuous regeneration without replanting. The processing requires minimal energy input, often utilizing solar power for drying and shaping processes. Advanced joining techniques using bio-based adhesives have eliminated the need for toxic chemicals traditionally used in composite manufacturing, creating frames that are completely biodegradable at the end of their useful life.

Recycled metals have undergone their own revolution in 2025, with new processing techniques allowing for the creation of high-grade aluminum and steel from post-consumer waste. These recycled materials now match or exceed the performance characteristics of virgin materials while requiring 95% less energy to produce. The closed-loop recycling systems implemented by leading manufacturers ensure that every bicycle frame can be completely recycled into new frames, creating a truly circular economy within the cycling industry.

Perhaps most exciting is the development of bio-based composite materials that combine the performance advantages of carbon fiber with complete environmental sustainability. These materials, derived from plant fibers and bio-based resins, offer weight and strength characteristics that rival traditional carbon fiber while being completely compostable at end of life. The manufacturing process for these bio-composites produces no toxic waste and requires significantly less energy than traditional composite production.

Carbon-Neutral Manufacturing Processes

The transformation of manufacturing processes represents the second pillar of the sustainable cycling revolution. Leading manufacturers have implemented comprehensive carbon-neutral production systems that eliminate the environmental impact of bicycle manufacturing while often improving efficiency and reducing costs.

Solar and wind power now provide the primary energy sources for most sustainable bicycle manufacturing facilities. These renewable energy systems, combined with advanced energy storage technologies, ensure consistent power availability while eliminating carbon emissions from the manufacturing process. The integration of smart grid technologies allows facilities to sell excess renewable energy back to the grid, often generating revenue that offsets manufacturing costs.

Water usage, traditionally a significant environmental concern in bicycle manufacturing, has been revolutionized through closed-loop systems that recycle and purify all water used in production processes. Advanced filtration and treatment systems ensure that no contaminated water leaves manufacturing facilities, while innovative cooling and cleaning processes have reduced overall water consumption by up to 80% compared to traditional methods.

Waste elimination has become a central focus of sustainable manufacturing, with leading facilities achieving zero-waste-to-landfill status through comprehensive recycling and reuse programs. Manufacturing scraps are immediately recycled into new components, while innovative partnerships with other industries have found uses for every byproduct of the manufacturing process. Some facilities have even achieved negative waste status by accepting and processing waste materials from other industries.

The implementation of lean manufacturing principles, combined with advanced automation and artificial intelligence, has optimized production processes to minimize energy consumption and material waste. Predictive maintenance systems ensure that manufacturing equipment operates at peak efficiency, while AI-driven quality control systems reduce defect rates and the associated waste from rejected components.

The Circular Economy in Action

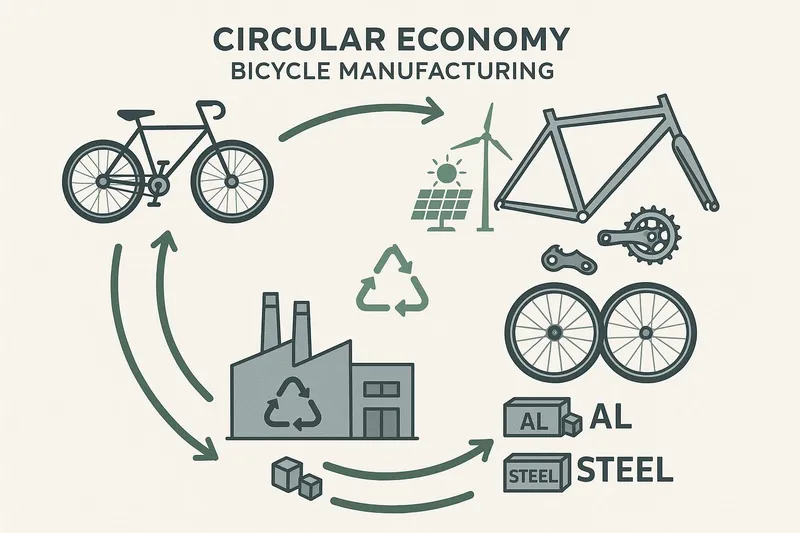

The concept of a circular economy has moved from theoretical framework to practical reality in the cycling industry, with comprehensive programs that ensure every component of a bicycle can be reused, recycled, or repurposed at the end of its useful life. This approach represents a fundamental shift from the traditional linear model of take-make-dispose to a regenerative system that eliminates waste and maximizes resource efficiency.

Take-back programs implemented by major manufacturers now provide convenient options for cyclists to return their old bicycles for complete recycling or refurbishment. These programs have evolved beyond simple collection services to comprehensive lifecycle management systems that track every component from initial production through multiple use cycles. Advanced disassembly techniques allow for the separation and categorization of materials with unprecedented precision, ensuring that each component finds its way to the most appropriate recycling or reuse application.

Component refurbishment has become a sophisticated industry in its own right, with specialized facilities capable of restoring used bicycle components to like-new condition. Advanced cleaning, inspection, and reconditioning processes can extend the useful life of components by decades, while quality assurance systems ensure that refurbished components meet or exceed original performance specifications. This refurbishment industry has created new employment opportunities while significantly reducing the demand for new component production.

The development of modular bicycle designs has facilitated the circular economy by making it easier to replace individual components rather than entire bicycles. These designs allow cyclists to upgrade specific components as technology advances while retaining the rest of their bicycle, dramatically extending the useful life of the overall system. Standardized interfaces and connection systems ensure compatibility across different manufacturers and model years, creating a truly interchangeable ecosystem of bicycle components.

Material recovery technologies have advanced to the point where complex composite materials can be broken down into their constituent elements for reuse in new products. Chemical recycling processes can separate carbon fibers from resin matrices, allowing both materials to be reused in new composite applications. These technologies have eliminated the previous barrier to recycling advanced composite materials, ensuring that even the most sophisticated bicycle components can be fully recovered and reused.

Consumer Demand and Market Response

The market response to sustainable cycling manufacturing has exceeded all expectations, with consumer demand driving rapid adoption of environmentally friendly production methods across the industry. Research conducted in 2025 reveals that environmental considerations now rank among the top three factors influencing bicycle purchasing decisions, alongside traditional concerns about performance and price.

Premium pricing for sustainable bicycles has proven to be less of a barrier than initially anticipated, with consumers demonstrating willingness to invest in products that align with their environmental values. The total cost of ownership for sustainable bicycles often proves lower than traditional alternatives when factors such as durability, repairability, and resale value are considered. Many sustainable bicycles demonstrate superior longevity compared to traditional models, while their modular designs facilitate cost-effective upgrades and repairs.

Brand loyalty has strengthened significantly for manufacturers that have embraced sustainable manufacturing practices. Consumers are increasingly viewing their bicycle purchases as expressions of personal values, leading to deeper emotional connections with brands that demonstrate genuine environmental commitment. This loyalty translates into repeat purchases, positive word-of-mouth marketing, and willingness to pay premium prices for new products from trusted sustainable manufacturers.

The rise of conscious consumerism has created new market segments focused specifically on environmental impact. These consumers actively seek out information about manufacturing processes, material sourcing, and end-of-life disposal options when making purchasing decisions. Manufacturers have responded by providing unprecedented transparency about their environmental practices, with detailed lifecycle assessments and carbon footprint calculations becoming standard marketing materials.

Corporate purchasing programs have emerged as a significant driver of sustainable bicycle adoption, with companies increasingly choosing environmentally friendly options for employee bike-to-work programs and corporate fleets. These bulk purchasing programs provide stable demand for sustainable manufacturers while demonstrating corporate environmental responsibility. The visibility of corporate sustainable bicycle programs has also increased consumer awareness and acceptance of environmentally friendly cycling options.

Future Implications and Industry Transformation

The sustainable manufacturing revolution in cycling represents just the beginning of a comprehensive transformation that will reshape the entire industry over the coming decades. Current trends suggest that sustainable manufacturing will become the standard rather than the exception, with traditional manufacturing methods becoming increasingly obsolete due to both environmental concerns and economic factors.

Technological advancement in sustainable materials continues to accelerate, with research into new bio-based composites, advanced recycling techniques, and innovative manufacturing processes promising even greater environmental benefits in the future. Nanotechnology applications are creating materials with unprecedented strength-to-weight ratios while maintaining complete environmental compatibility. These advances suggest that sustainable bicycles will not only match but exceed the performance characteristics of traditional models.

Regulatory pressure is increasing globally, with governments implementing stricter environmental standards for manufacturing processes and product lifecycle impacts. Extended producer responsibility laws are making manufacturers accountable for the entire lifecycle of their products, creating strong incentives for sustainable design and manufacturing practices. Carbon pricing mechanisms are making traditional energy-intensive manufacturing increasingly expensive while providing economic advantages to sustainable alternatives.

The integration of digital technologies with sustainable manufacturing is creating new possibilities for customization and efficiency. 3D printing with sustainable materials allows for on-demand production that eliminates inventory waste while enabling complete customization for individual cyclists. Digital twin technologies enable virtual testing and optimization of designs before physical production, reducing material waste and development time.

Supply chain transformation is extending sustainable practices beyond individual manufacturers to encompass entire production networks. Collaborative initiatives between manufacturers, suppliers, and logistics providers are creating integrated sustainable supply chains that optimize environmental impact across all stages of production and distribution. These collaborative approaches are proving more effective than individual company initiatives while creating industry-wide standards for sustainable practices.

The sustainable cycling manufacturing revolution of 2025 represents more than just an environmental initiative—it’s a fundamental reimagining of how products can be designed, manufactured, and integrated into a circular economy that benefits both consumers and the planet. As this revolution continues to unfold, it promises to transform not only the cycling industry but serve as a model for sustainable manufacturing across all sectors of the economy.

For cyclists seeking to make environmentally responsible choices, the abundance of sustainable options available in 2025 ensures that environmental consciousness no longer requires compromising on performance, quality, or style. The future of cycling is not only faster and more efficient but also more sustainable than ever before.