The bicycle maintenance landscape is undergoing a revolutionary transformation in 2025, driven by the integration of Internet of Things (IoT) sensors, artificial intelligence, and predictive analytics that are fundamentally changing how cyclists approach bike care. What was once a reactive process based on scheduled intervals or component failures has evolved into a sophisticated, data-driven system that anticipates maintenance needs before problems occur.

This smart maintenance revolution represents more than just technological advancement; it’s a complete paradigm shift that promises to reduce maintenance costs by 10-40% while halving the number of unexpected breakdowns. The implications extend far beyond professional cycling teams and bike-sharing fleets, offering recreational cyclists unprecedented insights into their bike’s health and performance optimization opportunities.

The convergence of sensor technology, machine learning algorithms, and cloud-based analytics has created maintenance ecosystems that continuously monitor every aspect of bicycle performance, from drivetrain efficiency to brake pad wear, tire pressure fluctuations to battery health in e-bikes. This comprehensive monitoring capability enables predictive maintenance strategies that were previously impossible with traditional inspection-based approaches.

The IoT Sensor Revolution in Bicycle Monitoring

The foundation of smart bike maintenance lies in the proliferation of sophisticated IoT sensors that can monitor virtually every component of a bicycle in real-time. These sensors, which have become increasingly miniaturized and energy-efficient, provide continuous data streams about component performance, wear patterns, and environmental conditions that affect bike health.

Modern IoT sensor systems for bicycles incorporate accelerometers, gyroscopes, temperature sensors, pressure monitors, and strain gauges that work together to create comprehensive pictures of bike performance and component health. These sensors can detect subtle changes in vibration patterns that indicate bearing wear, monitor chain stretch and lubrication levels, track brake pad thickness, and assess tire pressure variations throughout rides.

The data collection capabilities of these sensor systems have reached remarkable levels of sophistication, with some systems capable of monitoring over 50 different parameters simultaneously. This includes everything from pedaling efficiency and power transfer characteristics to environmental factors like humidity and temperature that affect component longevity. The sensors communicate wirelessly with smartphone apps and cloud-based platforms, creating seamless data integration that requires no user intervention.

Battery technology advances have enabled these sensor systems to operate for months or even years on single charges, while energy harvesting technologies allow some sensors to power themselves from the kinetic energy generated during riding. This eliminates the maintenance burden of the monitoring system itself, ensuring that the technology enhances rather than complicates the cycling experience.

The integration of these sensors with existing bike components has become increasingly seamless, with many manufacturers now incorporating monitoring capabilities directly into components during manufacturing. This integration approach eliminates the need for aftermarket sensor installation while providing more accurate and reliable monitoring capabilities.

Predictive Maintenance Algorithms and Machine Learning

The true power of smart bike maintenance lies not just in data collection, but in the sophisticated algorithms that analyze this data to predict maintenance needs with remarkable accuracy. Machine learning systems trained on vast datasets of bike performance and failure patterns can identify subtle indicators that precede component failures, often weeks or months before traditional inspection methods would detect problems.

These predictive algorithms consider multiple factors simultaneously, including usage patterns, environmental conditions, component age, and performance degradation trends to create personalized maintenance schedules for individual bikes. The systems learn from each bike’s unique usage patterns, adapting their predictions to account for factors like riding style, terrain preferences, and maintenance history.

The accuracy of these predictive systems has improved dramatically as the datasets used to train the algorithms have grown larger and more diverse. Current systems can predict chain replacement needs with over 95% accuracy, brake pad replacement with 90% accuracy, and tire replacement with 85% accuracy, significantly outperforming traditional time-based or mileage-based maintenance schedules.

Advanced algorithms also consider the interdependencies between different bike components, recognizing that wear in one component can accelerate wear in related components. For example, a worn chain can cause premature wear in cassette and chainring teeth, while improperly adjusted brakes can lead to rim or rotor damage. The predictive systems account for these relationships, providing holistic maintenance recommendations that optimize overall bike performance and longevity.

The integration of weather data and route information further enhances prediction accuracy, as the algorithms can account for the additional stress placed on components during challenging conditions. Rides in wet conditions, for example, accelerate chain wear and brake pad degradation, factors that the predictive systems incorporate into their maintenance recommendations.

Smart Diagnostic Tools and Connected Maintenance Equipment

The evolution of bike maintenance tools has paralleled the advancement in monitoring technology, with smart diagnostic tools that can communicate with bike sensors and provide detailed component analysis. These tools go far beyond traditional mechanical instruments, incorporating digital displays, wireless connectivity, and integrated databases that provide comprehensive maintenance guidance.

Modern smart torque wrenches, for example, not only ensure proper bolt tightening but also record torque specifications for each component, creating maintenance logs that track when components were last serviced and with what specifications. These tools can alert mechanics to potential over-tightening or under-tightening issues and provide recommendations based on manufacturer specifications and component age.

Digital chain checkers have evolved to provide precise wear measurements that integrate with predictive maintenance systems, automatically updating component health databases when measurements are taken. These tools can differentiate between different types of chain wear and provide specific recommendations for chain replacement timing based on drivetrain configuration and usage patterns.

Smart bike stands and work stations now incorporate weight sensors, alignment tools, and diagnostic interfaces that can perform comprehensive bike health assessments. These systems can detect frame alignment issues, wheel trueness problems, and component wear patterns that might not be apparent during casual inspection.

The integration of augmented reality technology into maintenance tools represents the cutting edge of smart bike care, with AR-enabled devices that can overlay maintenance instructions, torque specifications, and component information directly onto the bike being serviced. This technology reduces the likelihood of maintenance errors while providing step-by-step guidance for complex procedures.

Automated Maintenance Scheduling and Fleet Management

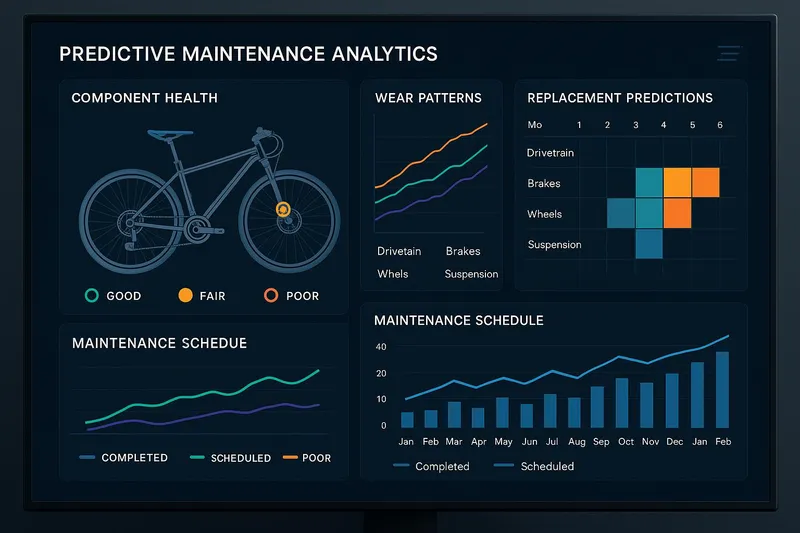

One of the most practical applications of smart bike maintenance technology has been in automated scheduling systems that eliminate the guesswork from maintenance planning. These systems analyze usage data, component wear patterns, and predictive algorithms to generate personalized maintenance schedules that optimize bike performance while minimizing unnecessary service interventions.

For individual cyclists, automated scheduling systems can integrate with calendar applications to suggest optimal maintenance windows based on riding schedules and component health status. The systems consider factors like upcoming events, seasonal riding patterns, and component lead times to ensure that maintenance is performed at the most convenient times without compromising bike reliability.

Fleet management applications of this technology have proven particularly valuable for bike-sharing systems, delivery services, and cycling teams that manage large numbers of bicycles. These systems can optimize maintenance schedules across entire fleets, ensuring that bikes are serviced efficiently while maintaining high availability rates for users.

The cost savings achieved through automated scheduling have been substantial, with fleet operators reporting 20-30% reductions in maintenance costs through optimized scheduling and predictive component replacement. The systems also reduce the administrative burden of maintenance management, automatically generating work orders, parts lists, and scheduling recommendations.

Integration with parts inventory systems ensures that necessary components are available when maintenance is scheduled, reducing downtime and improving service efficiency. Some systems can even automatically order replacement parts when predictive algorithms indicate that components are approaching replacement intervals.

Component Health Monitoring and Wear Analysis

The granular monitoring of individual bike components has reached unprecedented levels of sophistication, with sensors capable of tracking wear patterns, performance degradation, and failure indicators for virtually every part of a bicycle. This detailed monitoring enables maintenance strategies that optimize component life while ensuring reliable performance.

Drivetrain monitoring systems can track chain stretch, cassette wear, and chainring tooth wear with precision that exceeds traditional measurement tools. These systems consider factors like shifting quality, power transfer efficiency, and noise levels to provide comprehensive assessments of drivetrain health. The monitoring extends to derailleur alignment, cable tension, and shifting performance, creating complete pictures of drivetrain condition.

Brake system monitoring has become particularly sophisticated, with sensors that can track pad wear, rotor thickness, fluid levels in hydraulic systems, and braking performance characteristics. These systems can detect issues like brake fade, uneven pad wear, and hydraulic system leaks before they become safety concerns.

Wheel and tire monitoring systems track tire pressure, tread wear, wheel trueness, and spoke tension to ensure optimal rolling performance and safety. Advanced systems can detect slow leaks, uneven wear patterns, and wheel damage that might not be apparent during visual inspection.

Suspension monitoring for mountain bikes and e-bikes has evolved to track damping performance, seal condition, and service intervals based on actual usage rather than arbitrary time periods. These systems can detect performance degradation and recommend service before suspension performance is significantly compromised.

Integration with Professional Cycling and Performance Optimization

The adoption of smart maintenance technology in professional cycling has accelerated the development and refinement of these systems, with professional teams serving as testing grounds for advanced monitoring and predictive maintenance technologies. The demanding requirements of professional racing have pushed the boundaries of what’s possible in bike monitoring and maintenance optimization.

Professional teams now use comprehensive monitoring systems that track not only component wear but also performance optimization opportunities. These systems can identify aerodynamic inefficiencies, power transfer losses, and setup optimization opportunities that provide competitive advantages in racing situations.

The data collected from professional cycling applications has contributed to the development of more accurate predictive algorithms and better understanding of component wear patterns under extreme conditions. This knowledge has filtered down to consumer applications, improving the accuracy and reliability of smart maintenance systems for recreational cyclists.

Team mechanics now rely on predictive maintenance systems to ensure that bikes are in optimal condition for races while minimizing the risk of mechanical failures during competition. The systems can recommend component replacements, adjustments, and optimizations based on race schedules and performance requirements.

The integration of performance data with maintenance data has enabled new approaches to bike setup optimization, where maintenance decisions are made not just based on component condition but also on performance optimization opportunities. This holistic approach to bike care represents the future of cycling maintenance.

Consumer Applications and Accessibility

The democratization of smart bike maintenance technology has made sophisticated monitoring and predictive maintenance accessible to recreational cyclists, with consumer-grade systems that provide many of the benefits previously available only to professional teams and fleet operators. These systems have been designed for ease of use while maintaining the accuracy and reliability required for effective maintenance management.

Smartphone applications now serve as central hubs for bike maintenance management, integrating data from multiple sensors and providing user-friendly interfaces for maintenance tracking and scheduling. These apps can send notifications when maintenance is due, provide step-by-step maintenance instructions, and track maintenance history for warranty and resale purposes.

The cost of smart maintenance systems has decreased significantly as the technology has matured and production volumes have increased. Entry-level systems that provide basic monitoring and predictive maintenance capabilities are now available at price points that make them accessible to serious recreational cyclists.

DIY installation options have made smart maintenance technology more accessible, with many systems designed for easy installation without specialized tools or technical expertise. Comprehensive installation guides and video tutorials ensure that cyclists can successfully implement these systems on their own bikes.

The integration with existing cycling ecosystems, including training apps, route planning software, and social cycling platforms, has made smart maintenance technology a natural extension of the connected cycling experience that many cyclists already embrace.

Future Developments and Emerging Technologies

The trajectory of smart bike maintenance technology points toward even more sophisticated and integrated systems that will further transform how cyclists approach bike care and performance optimization. Emerging technologies promise to make maintenance even more predictive, automated, and seamlessly integrated into the cycling experience.

Artificial intelligence systems are becoming more sophisticated in their ability to predict maintenance needs and optimize bike performance, with machine learning algorithms that can adapt to individual riding styles and preferences. These systems will become increasingly personalized, providing maintenance recommendations that are tailored to specific cyclists and their unique usage patterns.

The integration of blockchain technology for maintenance records and component authentication represents an emerging trend that could revolutionize bike maintenance documentation and warranty management. Immutable maintenance records could provide valuable information for resale purposes while ensuring that warranty claims are properly documented.

Advanced materials with embedded sensors represent the next frontier in bike monitoring, with components that can monitor their own health and communicate directly with maintenance systems. These smart materials could eliminate the need for external sensors while providing even more accurate and comprehensive monitoring capabilities.

The development of autonomous maintenance systems that can perform basic maintenance tasks automatically represents a long-term vision for smart bike care. While still in early development, these systems could eventually handle tasks like chain lubrication, tire pressure adjustment, and basic component adjustments without human intervention.

As smart bike maintenance technology continues to evolve, it promises to make cycling more reliable, efficient, and enjoyable while reducing the time and cost associated with bike care. For cyclists looking to embrace these technological advances, the key is to start with systems that address their specific needs and gradually build more comprehensive monitoring and maintenance capabilities.

The smart bike maintenance revolution represents more than just technological innovation; it’s a fundamental shift toward data-driven bike care that optimizes performance, reduces costs, and enhances the overall cycling experience. As these technologies continue to mature and become more accessible, they promise to transform bike maintenance from a necessary chore into an integrated part of the connected cycling ecosystem.