The cycling industry is experiencing a profound transformation in 2025, with sustainability emerging as the defining force reshaping how bicycles are designed, manufactured, and brought to market. This revolution extends far beyond simple environmental consciousness to encompass fundamental changes in material sourcing, manufacturing processes, and supply chain management that are redefining what it means to create a bicycle in the modern era. The shift toward sustainable manufacturing represents one of the most significant developments in cycling technology since the introduction of carbon fiber, with implications that will resonate throughout the industry for decades to come.

The urgency driving this transformation stems from growing awareness of the environmental impact of traditional bicycle manufacturing, which has historically relied on energy-intensive processes and materials with significant carbon footprints. The cycling industry, despite promoting environmentally friendly transportation, has faced increasing scrutiny regarding its own environmental practices, particularly in the production of aluminum and carbon fiber components that form the backbone of modern bicycles. This apparent contradiction between the environmental benefits of cycling as transportation and the environmental costs of bicycle production has catalyzed a comprehensive reevaluation of manufacturing practices across the industry.

The year 2025 has emerged as a watershed moment for sustainable cycling manufacturing, marked by groundbreaking initiatives from major manufacturers that are setting new standards for environmental responsibility while maintaining the performance and quality expectations that define modern cycling. These developments represent not merely incremental improvements but fundamental shifts in how the industry approaches material selection, energy consumption, and waste reduction throughout the manufacturing process. The implications extend beyond environmental benefits to encompass economic advantages, supply chain resilience, and competitive differentiation that are reshaping the strategic landscape of the cycling industry.

The convergence of technological advancement, regulatory pressure, and consumer demand has created an unprecedented opportunity for the cycling industry to lead by example in sustainable manufacturing practices. This transformation is being driven by innovations in material science, renewable energy integration, and circular economy principles that are making sustainable manufacturing not only environmentally responsible but also economically viable and competitively advantageous. The result is a comprehensive reimagining of how bicycles are made, from the sourcing of raw materials to the end-of-life recycling of finished products.

The Trek Revolution: Industry-First Low-Emission Aluminum Initiative

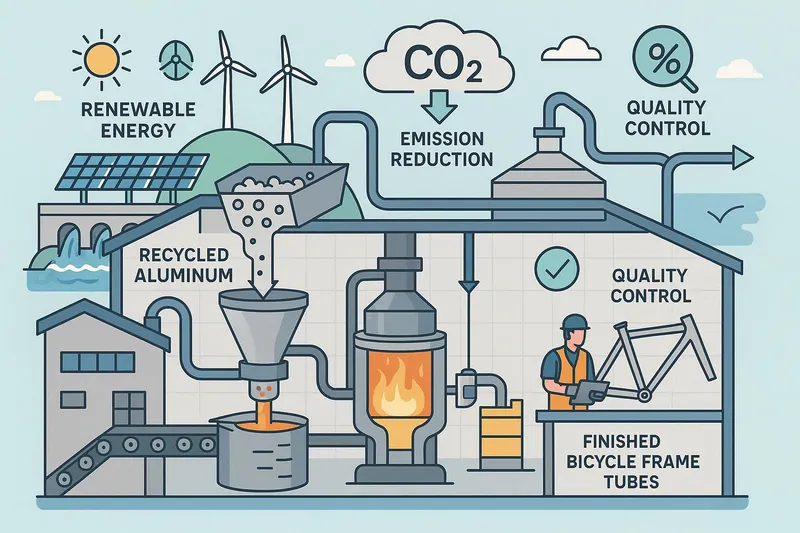

The most significant development in sustainable cycling manufacturing in 2025 has been Trek Bicycle Corporation’s announcement of an industry-first shift to low-emission aluminum across nearly its entire aluminum bicycle lineup. This groundbreaking initiative, announced in July 2025, represents the largest carbon-reduction effort in Trek’s history and sets a new benchmark for environmental responsibility in bicycle manufacturing. The scope and scale of this initiative, affecting well over one million bicycles annually, demonstrates that sustainable manufacturing can be implemented at industrial scale without compromising performance or quality.

Trek’s low-emission aluminum sourcing policy establishes a maximum emission threshold of 11 kilograms of CO₂ equivalent per kilogram of aluminum, aligning with the Aluminum Stewardship Initiative standards while pushing the industry toward more stringent environmental criteria. This standard represents a significant reduction from traditional aluminum production methods, which typically generate 15-20 kilograms of CO₂ equivalent per kilogram of material. The achievement of this standard requires fundamental changes in aluminum production, including the use of renewable energy sources, incorporation of recycled content, and optimization of smelting processes to minimize energy consumption and emissions.

The implementation of Trek’s low-emission aluminum initiative required extensive collaboration with suppliers and fundamental changes to established supply chains. The company began investigating lower-impact aluminum options in 2021, developing new sourcing policies and working directly with suppliers to meet updated environmental criteria. This collaborative approach demonstrates the complexity of implementing sustainable manufacturing practices at scale, requiring coordination across multiple tiers of suppliers and significant investment in supply chain transformation. The first low-emission aluminum Trek frame was produced in August 2024, with full implementation across the aluminum lineup scheduled for October 2025.

The technical specifications and performance characteristics of low-emission aluminum frames remain identical to traditional aluminum frames, addressing potential concerns about compromising performance for environmental benefits. This equivalence in functional performance while achieving significant environmental improvements demonstrates that sustainable manufacturing can deliver both environmental and performance benefits without requiring trade-offs. The maintenance of performance standards while achieving substantial emission reductions represents a significant technological achievement that validates the viability of sustainable manufacturing approaches across the cycling industry.

The economic implications of Trek’s low-emission aluminum initiative extend beyond the immediate environmental benefits to encompass supply chain resilience, cost stability, and competitive differentiation. By establishing long-term relationships with suppliers committed to sustainable practices, Trek is building supply chain resilience against future environmental regulations and carbon pricing mechanisms. The initiative also positions Trek as a leader in sustainable manufacturing, providing competitive advantages in markets where environmental considerations are increasingly important to consumers and institutional buyers.

The transparency and knowledge-sharing aspects of Trek’s initiative represent an important contribution to industry-wide transformation. The company has committed to sharing its sustainable aluminum sourcing policy with other manufacturers and industry organizations, recognizing that widespread adoption of sustainable practices requires collective action rather than competitive advantage. This collaborative approach to sustainability demonstrates the potential for industry-wide transformation when leading companies prioritize environmental responsibility over short-term competitive advantages.

Material Science Innovations Driving Sustainability

The sustainable manufacturing revolution in cycling is being powered by significant advances in material science that are enabling the development of environmentally responsible alternatives to traditional materials without compromising performance characteristics. These innovations span the entire spectrum of bicycle components, from frame materials to finishing processes, and represent fundamental breakthroughs in how materials are conceived, produced, and utilized in bicycle manufacturing. The convergence of environmental necessity and technological capability has accelerated the development of sustainable materials that were previously considered theoretical or economically unfeasible.

Bio-based resins and adhesives represent one of the most promising developments in sustainable cycling materials, offering the potential to replace petroleum-based chemicals with renewable alternatives derived from plant sources. These bio-based materials are being increasingly adopted in composite manufacturing, where they serve as the matrix material that binds carbon fibers together to create lightweight, high-strength components. The development of bio-based resins that match or exceed the performance characteristics of traditional petroleum-based alternatives represents a significant breakthrough in sustainable materials science, enabling the production of high-performance components with dramatically reduced environmental impact.

The advancement of recycled carbon fiber technology is revolutionizing the sustainability profile of high-performance cycling components. Traditional carbon fiber manufacturing has been criticized for its energy-intensive production process and the difficulty of recycling carbon fiber components at the end of their useful life. Recent developments in carbon fiber recycling technology, including mechanical recycling processes that preserve fiber strength and chemical recycling methods that recover usable carbon fibers from waste materials, are addressing these sustainability challenges while maintaining the performance advantages that make carbon fiber essential for high-performance cycling applications.

Focus Bicycles’ development of a recyclable carbon fiber frame using thermoplastic carbon fiber represents a significant breakthrough in sustainable composite manufacturing. Unlike traditional thermoset carbon fiber, which cannot be remelted and reformed, thermoplastic carbon fiber can be recycled at the end of its useful life, creating a circular economy for high-performance bicycle components. This innovation addresses one of the most significant sustainability challenges in modern bicycle manufacturing while maintaining the performance characteristics that make carbon fiber essential for competitive cycling applications.

The integration of recycled aluminum content in bicycle manufacturing is becoming increasingly sophisticated, with manufacturers developing processes that incorporate high percentages of recycled material without compromising structural integrity or performance characteristics. Advanced recycling technologies are enabling the production of aluminum alloys with recycled content exceeding 90% while maintaining the strength, durability, and weight characteristics required for high-performance bicycle applications. These developments are particularly significant given that aluminum recycling requires only 5% of the energy needed for primary aluminum production, offering substantial environmental benefits when implemented at scale.

The development of sustainable surface treatments and finishing processes is addressing the environmental impact of bicycle aesthetics and corrosion protection. Traditional anodizing and painting processes often involve toxic chemicals and energy-intensive procedures that contribute significantly to the environmental footprint of bicycle manufacturing. New sustainable finishing technologies, including powder coating systems that eliminate volatile organic compounds and bio-based protective coatings derived from renewable sources, are providing environmentally responsible alternatives that maintain the aesthetic and protective qualities expected in modern bicycle finishes.

Renewable Energy Integration in Manufacturing

The integration of renewable energy sources into bicycle manufacturing operations represents a fundamental shift in how the industry approaches energy consumption and carbon emissions. This transformation extends beyond simple electricity sourcing to encompass comprehensive energy management systems that optimize renewable energy utilization, minimize waste, and create resilient manufacturing operations that are less dependent on fossil fuel-based energy sources. The scale and sophistication of renewable energy integration in bicycle manufacturing has reached levels that were previously considered economically unfeasible, driven by dramatic reductions in renewable energy costs and advances in energy storage and management technologies.

Solar energy integration has become increasingly prevalent in bicycle manufacturing facilities, with many manufacturers installing large-scale photovoltaic systems that can provide significant portions of their energy needs. These installations often incorporate advanced energy storage systems that enable manufacturers to utilize solar energy even during periods when the sun is not shining, creating more consistent and reliable renewable energy supplies. The economic benefits of solar energy integration have improved dramatically in recent years, with many installations achieving payback periods of less than five years while providing decades of low-cost, environmentally responsible energy.

Wind energy partnerships are enabling bicycle manufacturers to access renewable energy at scales that would be impossible through on-site generation alone. Many manufacturers are entering into long-term power purchase agreements with wind energy developers, securing access to large quantities of renewable energy at predictable costs while supporting the development of new renewable energy capacity. These partnerships often involve innovative financing structures that enable manufacturers to access renewable energy without significant upfront capital investments, making renewable energy adoption accessible to manufacturers of all sizes.

Hydroelectric power utilization is particularly significant in regions where bicycle manufacturing is concentrated, such as Taiwan and parts of Europe where abundant hydroelectric resources are available. Manufacturers in these regions are increasingly prioritizing access to hydroelectric power, which provides consistent, renewable energy that is well-suited to the continuous operation requirements of modern manufacturing facilities. The reliability and consistency of hydroelectric power make it particularly valuable for energy-intensive manufacturing processes such as aluminum smelting and carbon fiber production.

Energy efficiency optimization is being pursued in parallel with renewable energy adoption, creating synergistic effects that maximize the environmental and economic benefits of sustainable energy practices. Advanced manufacturing equipment that incorporates energy recovery systems, variable speed drives, and intelligent control systems is reducing energy consumption while maintaining or improving production efficiency. These efficiency improvements reduce the total energy requirements of manufacturing operations, making renewable energy adoption more economically attractive while reducing the environmental impact of production.

The development of energy management systems that can optimize renewable energy utilization in real-time is enabling manufacturers to maximize the benefits of their renewable energy investments. These systems can automatically adjust production schedules to take advantage of periods when renewable energy is most abundant, shift energy-intensive processes to times when renewable energy costs are lowest, and integrate energy storage systems to smooth out variations in renewable energy availability. The sophistication of these energy management systems is enabling manufacturers to achieve renewable energy utilization rates that exceed 90% in some cases.

Circular Economy Principles in Bicycle Manufacturing

The adoption of circular economy principles in bicycle manufacturing represents a fundamental shift from the traditional linear “take-make-dispose” model to a regenerative approach that minimizes waste, maximizes resource utilization, and creates closed-loop systems that eliminate the concept of waste. This transformation requires comprehensive reimagining of product design, manufacturing processes, and end-of-life management to create systems that are inherently sustainable and economically viable. The implementation of circular economy principles in bicycle manufacturing is being driven by both environmental necessity and economic opportunity, as manufacturers discover that circular approaches can reduce costs while improving environmental performance.

Design for disassembly is becoming a fundamental principle in sustainable bicycle design, with manufacturers incorporating features that facilitate the separation and recovery of materials at the end of a bicycle’s useful life. This approach requires careful consideration of joining methods, material compatibility, and component accessibility to ensure that bicycles can be efficiently disassembled for material recovery. Advanced design software and lifecycle analysis tools are enabling manufacturers to optimize designs for both performance and end-of-life material recovery, creating products that deliver exceptional performance while minimizing environmental impact throughout their lifecycle.

Material recovery and recycling programs are being developed to capture and reprocess materials from end-of-life bicycles, creating closed-loop systems that reduce the need for virgin materials while providing economic value from waste streams. These programs often involve partnerships between manufacturers, retailers, and specialized recycling companies to create comprehensive collection and processing networks. The development of efficient material recovery processes is particularly important for high-value materials such as carbon fiber and aluminum alloys, where the economic value of recovered materials can justify the costs of collection and processing.

Component remanufacturing programs are extending the useful life of bicycle components while reducing the environmental impact of replacement parts. These programs involve the collection, refurbishment, and resale of used components that retain significant useful life, creating economic value while reducing waste. Advanced inspection and testing technologies are enabling remanufacturers to assess component condition accurately and restore components to like-new performance standards, creating high-quality alternatives to new components at reduced environmental and economic costs.

Modular design approaches are facilitating component upgrading and replacement while extending the useful life of bicycle frames and major components. By designing bicycles with standardized interfaces and modular components, manufacturers are enabling consumers to upgrade individual components rather than replacing entire bicycles, reducing waste while providing opportunities for performance improvements. This approach requires careful consideration of interface standards and component compatibility to ensure that modular designs provide the flexibility and performance expected by consumers.

The development of take-back programs is creating comprehensive systems for managing end-of-life bicycles while providing economic incentives for consumers to participate in circular economy initiatives. These programs often involve trade-in credits, recycling incentives, and component recovery services that make it economically attractive for consumers to return end-of-life bicycles rather than disposing of them through traditional waste streams. The success of these programs depends on creating convenient collection networks and providing sufficient economic incentives to overcome the inertia of traditional disposal methods.

Supply Chain Transformation and Transparency

The sustainable manufacturing revolution in cycling is driving comprehensive transformation of supply chains, with manufacturers implementing new standards for supplier selection, performance monitoring, and transparency that extend environmental responsibility throughout the entire value chain. This transformation requires fundamental changes in how manufacturers evaluate and manage supplier relationships, moving beyond traditional criteria of cost, quality, and delivery to incorporate environmental performance, social responsibility, and long-term sustainability. The complexity of modern bicycle supply chains, which often involve dozens of suppliers across multiple countries, makes this transformation particularly challenging but also critically important for achieving meaningful environmental improvements.

Supplier sustainability certification programs are being implemented to ensure that environmental standards are maintained throughout the supply chain, with manufacturers requiring suppliers to meet specific environmental criteria and undergo regular auditing to verify compliance. These certification programs often incorporate third-party verification and standardized assessment criteria to ensure consistency and credibility. The development of industry-wide sustainability standards is facilitating the implementation of these programs by providing common frameworks that can be applied across different suppliers and manufacturing contexts.

Carbon footprint tracking and reporting systems are being implemented throughout bicycle supply chains to provide visibility into the environmental impact of different suppliers and manufacturing processes. These systems often incorporate sophisticated data collection and analysis tools that can track emissions at the component level, enabling manufacturers to identify opportunities for improvement and make informed decisions about supplier selection and process optimization. The granularity and accuracy of these tracking systems are improving rapidly as data collection technologies advance and standardized reporting frameworks are adopted.

Local sourcing initiatives are being pursued to reduce transportation-related emissions while supporting regional economic development and improving supply chain resilience. These initiatives often involve the development of new supplier relationships and the establishment of regional manufacturing capabilities that can reduce the distance between suppliers and final assembly operations. The success of local sourcing initiatives depends on balancing environmental benefits with cost considerations and ensuring that local suppliers can meet the quality and performance standards required for modern bicycle manufacturing.

Supplier development programs are being implemented to help existing suppliers improve their environmental performance while maintaining the quality and cost competitiveness required for successful business relationships. These programs often involve technical assistance, training, and financial support to help suppliers implement environmental improvements that might otherwise be economically challenging. The collaborative nature of these programs reflects the recognition that sustainable supply chains require partnership and mutual investment rather than simply imposing requirements on suppliers.

Transparency and traceability systems are being developed to provide consumers and stakeholders with detailed information about the environmental impact and sourcing practices associated with specific bicycles and components. These systems often incorporate blockchain technology and other advanced tracking methods to create immutable records of supply chain activities and environmental performance. The development of consumer-facing transparency tools is enabling environmentally conscious consumers to make informed purchasing decisions while creating market incentives for continued environmental improvement.

Economic Implications and Market Dynamics

The sustainable manufacturing revolution in cycling is creating significant economic implications that extend far beyond the immediate costs of implementing environmental improvements, encompassing changes in competitive dynamics, consumer preferences, regulatory compliance, and long-term business sustainability. These economic effects are reshaping the strategic landscape of the cycling industry, creating new opportunities for differentiation while imposing new requirements for competitiveness. The economic viability of sustainable manufacturing practices is improving rapidly as technologies mature, costs decline, and market demand for environmentally responsible products increases.

Cost-benefit analysis of sustainable manufacturing initiatives reveals increasingly favorable economic returns as environmental technologies mature and scale effects reduce implementation costs. The initial investments required for sustainable manufacturing often involve significant upfront costs for new equipment, supplier development, and process optimization, but these investments are increasingly generating positive returns through reduced operating costs, improved efficiency, and premium pricing opportunities. The payback periods for sustainable manufacturing investments are decreasing as technologies improve and market demand for sustainable products increases.

Premium pricing opportunities for sustainably manufactured bicycles are creating new revenue streams that can offset the costs of environmental improvements while providing competitive advantages in environmentally conscious market segments. Consumer willingness to pay premiums for environmentally responsible products is increasing, particularly in developed markets where environmental awareness is high and disposable income levels support premium pricing. The ability to command premium prices for sustainable products is creating economic incentives for continued environmental improvement while validating the business case for sustainable manufacturing.

Regulatory compliance advantages are becoming increasingly important as governments implement new environmental regulations and carbon pricing mechanisms that favor sustainable manufacturing practices. Manufacturers that proactively implement sustainable practices are better positioned to comply with emerging regulations while avoiding the costs and disruptions associated with reactive compliance efforts. The anticipation of future regulatory requirements is driving current investments in sustainable manufacturing as companies seek to avoid the higher costs and competitive disadvantages associated with delayed compliance.

Supply chain resilience benefits are providing economic value through reduced exposure to commodity price volatility, supply disruptions, and regulatory changes that can affect traditional supply chains. Sustainable supply chains often incorporate diversified sourcing strategies, local supplier development, and circular economy principles that reduce dependence on volatile global commodity markets while improving resilience against supply disruptions. These resilience benefits are becoming increasingly valuable as global supply chains face growing uncertainties from geopolitical tensions, climate change, and other systemic risks.

Investment and financing advantages are emerging as financial institutions increasingly incorporate environmental criteria into their lending and investment decisions. Manufacturers with strong sustainability credentials are finding improved access to capital, lower borrowing costs, and enhanced investor interest that can provide significant competitive advantages. The growing importance of environmental, social, and governance (ESG) criteria in investment decisions is creating financial incentives for sustainable manufacturing that complement market-based incentives.

Consumer Awareness and Market Demand

The growing consumer awareness of environmental issues and the environmental impact of manufacturing processes is creating significant market demand for sustainably manufactured bicycles, driving industry transformation while creating new opportunities for differentiation and premium positioning. This consumer awareness extends beyond simple environmental consciousness to encompass sophisticated understanding of supply chain practices, material sourcing, and lifecycle environmental impacts that is enabling consumers to make informed purchasing decisions based on environmental criteria. The depth and sophistication of consumer environmental awareness is increasing rapidly, driven by improved access to information, growing environmental education, and increasing concern about climate change and environmental degradation.

Environmental consciousness among cyclists is particularly high due to the inherent environmental benefits of cycling as transportation and the outdoor recreation focus that characterizes much of cycling culture. This environmental consciousness creates natural alignment between cycling participation and environmental responsibility, making cyclists particularly receptive to sustainable manufacturing messages and willing to support companies that demonstrate genuine environmental commitment. The authenticity and credibility of environmental claims are particularly important to cycling consumers, who often have high levels of technical knowledge and environmental awareness that enable them to evaluate sustainability claims critically.

Generational differences in environmental priorities are creating distinct market segments with different expectations and willingness to pay for sustainable products. Younger consumers, particularly millennials and Generation Z, demonstrate significantly higher levels of environmental consciousness and willingness to pay premiums for sustainable products compared to older generations. These generational differences are driving long-term shifts in market demand that favor sustainable manufacturing while creating opportunities for brands that can effectively communicate their environmental credentials to younger consumers.

Corporate and institutional purchasing decisions are increasingly incorporating environmental criteria, creating large-scale market demand for sustainably manufactured bicycles in fleet, rental, and bike-sharing applications. Corporate sustainability commitments and institutional environmental policies are driving procurement decisions that prioritize environmental performance alongside traditional criteria of cost, quality, and performance. The scale of corporate and institutional purchasing can provide significant market opportunities for manufacturers that can meet environmental criteria while maintaining competitive pricing and performance.

Certification and labeling programs are providing consumers with standardized information about the environmental performance of bicycles and components, enabling informed purchasing decisions while creating market incentives for environmental improvement. These programs often incorporate third-party verification and standardized assessment criteria to ensure credibility and comparability across different products and manufacturers. The effectiveness of certification programs depends on consumer awareness and trust, which are developing as programs mature and demonstrate their value in identifying genuinely sustainable products.

Social media and digital communication channels are amplifying consumer awareness of environmental issues while providing platforms for sharing information about sustainable products and manufacturing practices. The viral nature of social media communication can rapidly spread awareness of both positive and negative environmental practices, creating powerful incentives for manufacturers to maintain high environmental standards while providing opportunities for effective communication of sustainability achievements. The authenticity and transparency of environmental communication are particularly important in social media contexts, where misleading or exaggerated claims can quickly generate negative publicity.

For cyclists interested in exploring how technology is transforming other aspects of the cycling experience, our comprehensive guides on advanced cycling technology, cycling performance and health optimization, and AI-powered cycling provide detailed insights into the latest developments in cycling technology and their practical applications for riders seeking to optimize their performance and enjoyment.