The cycling industry is witnessing a fundamental transformation in wheel technology that promises to redefine performance, efficiency, and the very nature of cycling itself. The year 2025 has emerged as a pivotal moment when revolutionary innovations in spoke technology and wheel sizing are converging to create possibilities that seemed like science fiction just a few years ago.

From the emergence of fiber-based spoke systems that challenge century-old steel wire conventions to the development of massive 32-inch wheels that push the boundaries of what we consider practical for cycling, the wheel technology revolution is reshaping every aspect of bicycle design and performance. These innovations aren’t just incremental improvements—they represent paradigm shifts that are forcing the entire cycling industry to reconsider fundamental assumptions about wheel design, performance optimization, and rider experience.

This technological revolution extends far beyond professional racing, influencing everything from mountain biking and gravel cycling to urban transportation and recreational riding. The implications are so significant that they’re driving changes in frame design, component compatibility, and even the basic geometry of bicycles themselves.

The Fiber Spoke Revolution: Redefining Wheel Construction

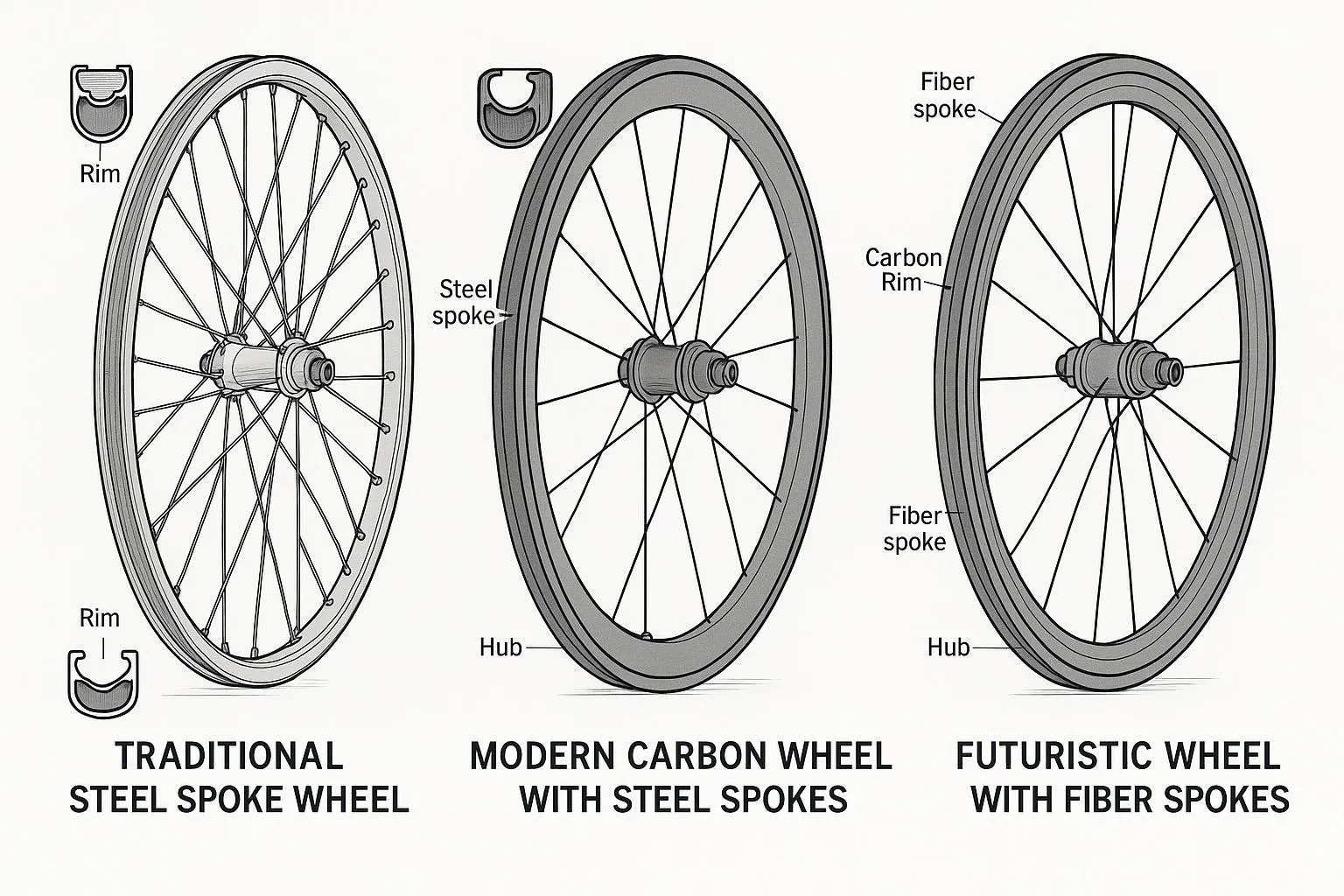

The most immediately transformative development in wheel technology is the rapid adoption and refinement of fiber-based spoke systems. While companies like Berd and Spinergy pioneered this technology, 2025 has seen an explosion of innovation and competition that’s driving fiber spokes from niche specialty products to mainstream cycling components [1].

The entry of major spoke manufacturer Sapim into the fiber spoke market represents a watershed moment for this technology [1]. Sapim’s involvement signals that fiber spokes have moved beyond experimental status to become a viable commercial technology with broad market potential. When established manufacturers with extensive distribution networks and quality control systems embrace new technologies, it typically indicates that those technologies are ready for widespread adoption.

The technical advantages of fiber spokes are compelling and multifaceted. Unlike traditional steel spokes, fiber spokes offer superior vibration damping characteristics that can significantly improve ride quality and reduce rider fatigue during long rides. This vibration damping doesn’t just enhance comfort—it can also improve control and handling by reducing the transmission of road surface irregularities to the rider.

Weight reduction represents another significant advantage of fiber spoke technology. High-quality fiber spokes can reduce wheel weight by substantial amounts compared to equivalent steel spoke systems, contributing to improved acceleration, climbing performance, and overall bike handling. This weight reduction is particularly valuable in competitive cycling applications where every gram matters.

The aerodynamic properties of fiber spokes also offer advantages over traditional steel spokes. The ability to shape fiber spokes with aerodynamic profiles that would be impossible or impractical with steel wire opens new possibilities for wheel aerodynamics. This capability is particularly relevant as the cycling industry continues to focus on aerodynamic optimization across all disciplines.

Durability and reliability concerns that initially limited fiber spoke adoption are being addressed through improved materials and manufacturing processes. Modern fiber spokes demonstrate excellent fatigue resistance and can withstand the demanding conditions of competitive cycling and aggressive recreational riding. The development of reliable field repair techniques and improved spoke replacement procedures is also addressing practical concerns about maintenance and serviceability.

Chinese Innovation and Market Competition

The fiber spoke revolution is being accelerated by intense competition from Chinese manufacturers who are bringing innovative approaches and competitive pricing to the market. Companies like Goosyn are developing fiber spoke products that appear to be derivative of established designs while potentially offering cost advantages and manufacturing scalability [1].

This competitive pressure is driving rapid innovation and improvement across the entire fiber spoke market. Established manufacturers are being forced to accelerate their development programs and improve their value propositions, while new entrants are bringing fresh perspectives and manufacturing capabilities to the technology.

The globalization of fiber spoke technology is also improving availability and reducing costs for consumers. As manufacturing scales up and competition intensifies, fiber spokes are becoming more accessible to a broader range of cyclists, supporting wider adoption and market growth.

Quality control and standardization represent ongoing challenges as the fiber spoke market expands. Different manufacturers are using varying materials, construction techniques, and quality standards, creating potential compatibility and reliability issues. The development of industry standards and testing protocols will be crucial for ensuring consistent quality and performance across different fiber spoke products.

The 32-Inch Wheel Revolution: Bigger is Better?

Perhaps the most radical development in wheel technology is the emergence of 32-inch wheels for mountain biking and gravel cycling applications. This development challenges fundamental assumptions about optimal wheel sizing and opens possibilities for entirely new categories of cycling performance [1].

The advocacy of cycling legend Gary Fisher for 32-inch wheels brings significant credibility and attention to this emerging technology [1]. Fisher’s claim that he has developed a mountain bike design that would accommodate 32-inch wheels while remaining suitable for riders as short as 5’5″ addresses one of the primary concerns about larger wheel sizes—their impact on bike geometry and rider fit.

The theoretical advantages of larger wheels are well-established in cycling physics. Larger wheels roll over obstacles more easily, maintain momentum more effectively, and can provide improved traction and stability in challenging terrain. These advantages have driven the evolution from 26-inch to 29-inch wheels in mountain biking, and the same principles suggest that even larger wheels could provide additional benefits.

The development of 32-inch tires by major manufacturers like Maxxis represents a crucial step toward commercial viability for this technology [1]. The availability of the Maxxis Aspen in 32-inch sizing indicates that at least one major tire manufacturer believes there’s sufficient market potential to justify the development and production costs associated with this new size.

Early testing feedback suggests “guarded optimism” about 32-inch wheel performance [1]. While this measured response indicates that the technology isn’t yet fully mature, it also suggests that the fundamental concept has merit and that continued development could address current limitations.

The engineering challenges associated with 32-inch wheels are substantial. Frame geometry must be completely reconsidered to accommodate the larger wheels while maintaining appropriate handling characteristics and rider fit. Suspension systems, if used, must be redesigned to work effectively with the altered geometry and different wheel characteristics.

Impact on Bike Design and Geometry

The wheel technology revolution is forcing fundamental reconsiderations of bicycle design and geometry. Both fiber spokes and larger wheel sizes have implications that extend far beyond the wheels themselves, influencing frame design, component selection, and overall bike architecture.

Fiber spoke wheels can enable different approaches to frame design because of their superior vibration damping characteristics. Frames can potentially be designed with different stiffness characteristics when paired with fiber spoke wheels, optimizing the overall system for specific performance goals or ride quality objectives.

The integration of fiber spoke wheels with modern aerodynamic frame designs creates opportunities for system-level optimization that wouldn’t be possible with traditional steel spoke wheels. The ability to shape fiber spokes for aerodynamic performance allows wheel and frame designers to work together to optimize airflow around the entire bike system.

Larger wheel sizes require more dramatic changes to bike geometry and design. The increased wheel diameter affects everything from bottom bracket height and chainstay length to head tube angle and fork design. These changes can significantly alter bike handling characteristics and require careful engineering to maintain desirable performance attributes.

The development of bikes designed specifically for larger wheels also creates opportunities to optimize other aspects of bike design. Suspension systems, drivetrain configurations, and component integration can all be reconsidered when designing around larger wheel sizes, potentially leading to performance improvements that extend beyond just the wheel size change.

Performance Implications Across Cycling Disciplines

The wheel technology revolution has different implications for various cycling disciplines, with some applications showing more immediate promise than others. Understanding these discipline-specific impacts is crucial for cyclists considering whether and how to adopt these new technologies.

Mountain biking represents perhaps the most promising application for both fiber spokes and larger wheels. The vibration damping characteristics of fiber spokes can significantly improve comfort and control on rough terrain, while larger wheels offer improved rollover capability and momentum maintenance. The combination of these technologies could create mountain bikes with substantially improved performance characteristics.

Gravel cycling is another discipline where wheel technology innovations show significant promise. The mixed terrain and long-distance nature of gravel riding make both vibration damping and improved rollover characteristics valuable. The development of aerodynamic fiber spoke wheels specifically for gravel applications could provide performance advantages in competitive gravel racing.

Road cycling applications for these technologies are more complex. While fiber spokes offer aerodynamic and weight advantages that are valuable in road racing, the benefits of larger wheels are less clear for smooth pavement applications. However, the integration of fiber spoke technology with advanced cycling technology could create new possibilities for road bike performance optimization.

Cyclocross and bike racing disciplines present interesting applications for wheel technology innovations. The varied terrain and demanding conditions of these disciplines could benefit from both the vibration damping of fiber spokes and the improved rollover characteristics of larger wheels, though the specific requirements of each discipline would need to be carefully considered.

Urban and commuter cycling represents a potentially large market for wheel technology innovations, particularly if they can improve comfort, durability, and performance for everyday transportation cycling. The practical benefits of improved ride quality and reduced maintenance requirements could make these technologies attractive to a broad range of urban cyclists.

Manufacturing and Production Challenges

The wheel technology revolution faces significant manufacturing and production challenges that must be addressed for widespread adoption. These challenges span materials science, production processes, quality control, and supply chain management.

Fiber spoke manufacturing requires specialized equipment and expertise that differs significantly from traditional steel spoke production. The development of efficient, scalable production processes for fiber spokes is crucial for achieving the cost levels necessary for broad market adoption. This transition requires significant capital investment and technical expertise development across the manufacturing supply chain.

Quality control for fiber spokes presents unique challenges because traditional testing methods developed for steel spokes may not be appropriate for fiber materials. New testing protocols and quality assurance procedures must be developed to ensure consistent performance and reliability across different production batches and manufacturers.

The production of 32-inch wheels and tires requires modifications to existing manufacturing equipment and processes. Tire manufacturing equipment must be adapted or replaced to handle the larger sizes, while wheel building processes must be adjusted to accommodate the different spoke lengths and tensions required for larger wheels.

Supply chain coordination becomes more complex as wheel technology innovations require closer integration between spoke manufacturers, rim producers, tire companies, and bike manufacturers. This coordination is essential for ensuring compatibility and optimizing system-level performance across different component combinations.

Market Adoption and Consumer Acceptance

The success of wheel technology innovations depends heavily on market adoption and consumer acceptance, which are influenced by factors beyond just technical performance. Price, availability, serviceability, and perceived value all play crucial roles in determining whether new technologies achieve widespread adoption.

Early adopters of fiber spoke technology tend to be performance-oriented cyclists who value the technical advantages and are willing to pay premium prices for cutting-edge equipment. As production scales up and costs decrease, adoption is likely to expand to broader market segments, particularly if the technology demonstrates clear performance and durability advantages.

The adoption of larger wheel sizes faces different challenges, as it requires not just new wheels but potentially new bikes designed specifically for the larger wheels. This requirement creates a higher barrier to adoption and means that market acceptance will likely depend on the development of complete bike systems that demonstrate clear advantages over existing alternatives.

Consumer education plays a crucial role in the adoption of wheel technology innovations. Many cyclists may not understand the technical advantages of fiber spokes or larger wheels, making it important for manufacturers and retailers to effectively communicate the benefits and applications of these technologies.

The development of upgrade paths and retrofit options could accelerate adoption by allowing existing bike owners to experience the benefits of new wheel technologies without purchasing entirely new bikes. This approach is more feasible for fiber spoke wheels than for larger wheel sizes, which typically require frame modifications or replacement.

Integration with Electronic and Smart Technologies

The wheel technology revolution is occurring alongside rapid developments in electronic and smart cycling technologies, creating opportunities for integration that could enhance the benefits of both trends. The combination of advanced wheel technologies with electronic systems could create entirely new categories of cycling performance and functionality.

Fiber spoke wheels offer unique opportunities for integrating electronic components because of their construction characteristics. Sensors, wiring, and electronic components could potentially be integrated into fiber spoke designs in ways that would be difficult or impossible with traditional steel spokes.