The cycling industry is experiencing a maintenance revolution that’s fundamentally changing how we care for our bikes. Gone are the days of guesswork and reactive repairs—2025 has ushered in an era of smart bike maintenance powered by artificial intelligence, Internet of Things (IoT) sensors, and automated systems that can predict, diagnose, and even perform maintenance tasks with unprecedented precision and efficiency.

This technological transformation represents more than just convenience; it’s a paradigm shift that’s making professional-level bike care accessible to everyday cyclists while reducing costs, improving safety, and extending the lifespan of cycling equipment. From AI-powered diagnostic tools that can identify potential issues before they become problems to automated washing systems that clean bikes with robotic precision, the smart maintenance revolution is reshaping every aspect of bicycle care.

The integration of these technologies addresses long-standing challenges in the cycling community, where proper maintenance has often been a barrier to optimal performance and safety. Traditional bike maintenance required extensive knowledge, specialized tools, and significant time investment—factors that often led to neglected maintenance schedules and unexpected mechanical failures. Smart maintenance systems are democratizing bike care by making it more accessible, accurate, and proactive.

As we explored in our comprehensive guide to cycling training optimization, proper bike maintenance is crucial for performance and safety. The smart maintenance revolution takes this principle to the next level by ensuring that maintenance becomes an integrated, automated part of the cycling experience rather than a separate, often-neglected responsibility.

The AI-Powered Diagnostic Revolution

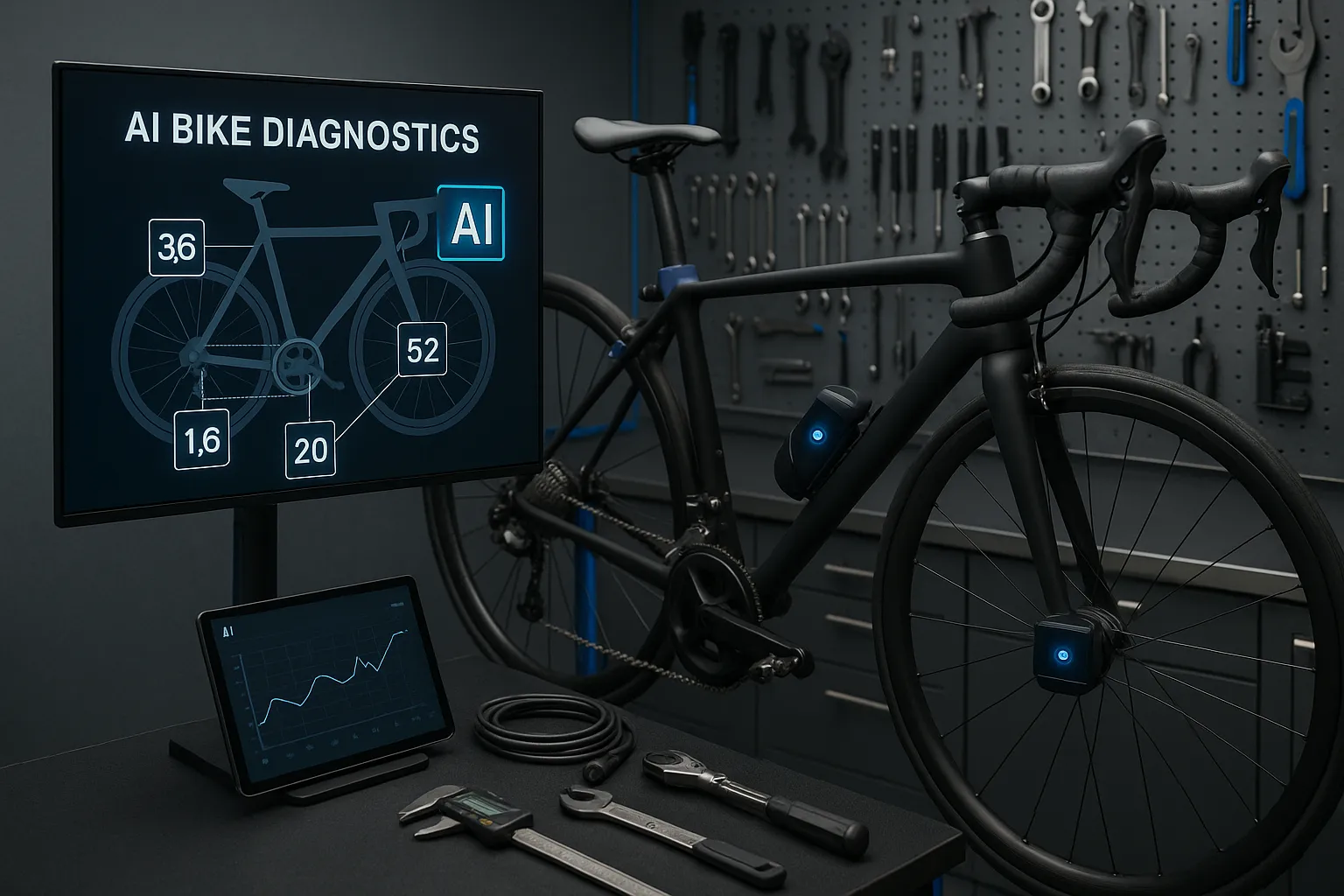

Artificial intelligence has emerged as the cornerstone of modern bike maintenance, transforming how we identify, analyze, and address mechanical issues. AI-powered diagnostic systems use sophisticated algorithms, machine learning models, and sensor networks to provide real-time analysis of bike performance and condition, offering insights that were previously available only to experienced mechanics with years of training.

These systems work by continuously monitoring various bike components through strategically placed sensors that track metrics such as component wear patterns, stress levels, vibration signatures, and performance degradation over time. The AI algorithms analyze this data against vast databases of known failure patterns and maintenance requirements, enabling them to predict potential issues weeks or even months before they would become apparent to human observation.

The diagnostic capabilities extend far beyond simple component monitoring. Modern AI systems can analyze riding patterns, environmental conditions, and usage intensity to create personalized maintenance schedules that optimize both performance and component longevity. This level of customization ensures that each bike receives exactly the care it needs based on its specific usage patterns and operating conditions.

One of the most significant advantages of AI diagnostics is their ability to learn and improve over time. As these systems process more data from various bikes and riding conditions, their predictive accuracy increases, leading to more precise maintenance recommendations and fewer unexpected failures. This continuous learning capability means that the technology becomes more valuable and reliable as it gains experience with different bike types, components, and usage patterns.

The integration of AI diagnostics with mobile applications has made this technology accessible to cyclists of all skill levels. Modern diagnostic apps can interpret complex sensor data and present it in user-friendly formats, providing clear recommendations for maintenance actions, component replacements, and performance optimizations. This accessibility is crucial for widespread adoption and ensures that the benefits of AI-powered maintenance extend beyond professional mechanics to everyday cyclists.

Automated Cleaning Systems: The Future of Bike Washing

The development of automated bike cleaning systems represents one of the most visible and immediately practical applications of smart maintenance technology. These sophisticated machines use robotic brushes, precision water jets, and intelligent cleaning algorithms to provide thorough, consistent cleaning that surpasses traditional manual methods while reducing time, effort, and water consumption.

Modern automated cleaning systems, such as the innovative Velobrush technology, employ computer vision and machine learning to identify different bike components and apply appropriate cleaning techniques for each area. The systems can distinguish between delicate electronic components that require gentle treatment and robust mechanical parts that can withstand more aggressive cleaning, ensuring optimal results without risk of damage.

The precision of these automated systems extends to their use of cleaning agents and water. Advanced systems can adjust cleaning intensity, duration, and chemical concentration based on the level of contamination detected, the type of dirt or grime present, and the specific materials being cleaned. This intelligent approach not only improves cleaning effectiveness but also minimizes environmental impact by using only the necessary amount of resources.

The time savings provided by automated cleaning systems are substantial, with most systems capable of completing a thorough bike wash in under ten minutes compared to the 30-45 minutes typically required for manual cleaning. This efficiency makes regular cleaning more practical for busy cyclists and encourages better maintenance habits by removing one of the primary barriers to consistent bike care.

Beyond individual convenience, automated cleaning systems are transforming commercial bike maintenance operations. Bike shops, rental facilities, and fleet operators can process significantly more bikes with consistent quality while reducing labor costs and improving customer satisfaction. The systems also provide detailed cleaning reports and can integrate with broader maintenance management systems to track service history and schedule follow-up maintenance.

Smart Repair Stands and Workshop Innovation

The evolution of bike repair equipment has reached new heights with the introduction of smart repair stands and intelligent workshop tools that enhance both efficiency and precision in bike maintenance. Electric height-adjustable repair stands represent a significant advancement over traditional manual systems, offering precise positioning control, ergonomic benefits, and integration with digital maintenance systems.

These advanced repair stands feature programmable height settings, rotation controls, and clamping systems that can be adjusted with millimeter precision using digital controls. The ability to save and recall specific positioning settings for different bike types and maintenance tasks significantly improves workflow efficiency and reduces setup time for mechanics working on multiple bikes throughout the day.

The integration of smart repair stands with diagnostic systems creates a comprehensive maintenance environment where bike positioning, component access, and diagnostic data are seamlessly coordinated. Mechanics can access real-time diagnostic information while working on specific components, with the repair stand automatically positioning the bike for optimal access to areas requiring attention.

Advanced workshop management systems now incorporate these smart tools into broader maintenance workflows, tracking repair progress, component replacement schedules, and quality control metrics. This integration ensures that maintenance tasks are completed efficiently and consistently while maintaining detailed records for warranty purposes and future reference.

The ergonomic benefits of smart repair stands cannot be overstated, particularly for professional mechanics who spend hours each day working on bikes. Electric height adjustment eliminates the physical strain associated with manual positioning systems, while programmable settings ensure optimal working positions for different tasks and mechanic preferences. These improvements contribute to better work quality, reduced fatigue, and lower risk of workplace injuries.

IoT Sensors and Predictive Maintenance

The Internet of Things has revolutionized bike maintenance through the deployment of sophisticated sensor networks that continuously monitor bike performance and condition. These tiny, lightweight sensors can be integrated into various bike components to track metrics such as component wear, stress levels, temperature variations, and performance degradation in real-time.

Modern IoT sensor systems are designed to be unobtrusive and energy-efficient, with many sensors capable of operating for months or even years on a single battery charge. The sensors communicate wirelessly with smartphone apps or dedicated monitoring systems, providing continuous data streams that enable predictive maintenance strategies previously impossible with traditional inspection methods.

The predictive capabilities of IoT-enabled maintenance systems represent a fundamental shift from reactive to proactive bike care. Instead of waiting for components to fail or show obvious signs of wear, these systems can identify developing issues weeks or months in advance, allowing for planned maintenance that minimizes downtime and prevents more serious problems from developing.

The data collected by IoT sensors extends beyond simple component monitoring to include environmental factors, usage patterns, and performance trends that influence maintenance requirements. This comprehensive data collection enables the development of highly personalized maintenance schedules that account for individual riding styles, local conditions, and specific bike configurations.

Integration with mobile applications makes IoT sensor data accessible and actionable for cyclists of all technical backgrounds. Modern apps can interpret complex sensor data and present it in intuitive formats, providing clear recommendations for maintenance actions, component replacements, and performance optimizations. Push notifications and automated scheduling features ensure that important maintenance tasks are never overlooked.

Mobile Apps and Digital Maintenance Management

The proliferation of sophisticated mobile applications has democratized access to professional-level bike maintenance knowledge and tools. Modern maintenance apps combine IoT sensor data, AI-powered diagnostics, and comprehensive maintenance databases to provide personalized care recommendations that rival the expertise of experienced mechanics.

These applications serve as digital maintenance assistants, tracking service history, monitoring component wear, and providing step-by-step guidance for various maintenance tasks. The integration of augmented reality features in some apps allows users to visualize maintenance procedures directly on their bikes, making complex tasks more accessible to novice mechanics.

The scheduling and reminder features of maintenance apps address one of the most common causes of bike problems: neglected maintenance. Automated scheduling based on mileage, time intervals, and component-specific requirements ensures that critical maintenance tasks are performed at optimal intervals, preventing minor issues from developing into major problems.

Advanced apps also provide access to extensive databases of maintenance procedures, troubleshooting guides, and component specifications. This information is often presented in multimedia formats with videos, interactive diagrams, and step-by-step instructions that make complex maintenance tasks more approachable for cyclists with varying levels of technical expertise.

The social and community features of many maintenance apps create networks of cyclists who can share experiences, recommendations, and troubleshooting advice. This collaborative approach to maintenance knowledge sharing helps build a more informed and capable cycling community while providing support for cyclists tackling challenging maintenance tasks.

Cost-Benefit Analysis of Smart Maintenance Systems

The financial implications of smart maintenance technology extend far beyond the initial investment in equipment and systems. While the upfront costs of AI diagnostic tools, automated cleaning systems, and IoT sensors may seem substantial, the long-term benefits typically result in significant cost savings and improved value for cyclists and bike shops alike.

The primary cost savings come from the prevention of major mechanical failures through predictive maintenance. Traditional reactive maintenance often results in expensive emergency repairs, component replacements, and extended downtime that can cost hundreds or even thousands of dollars. Smart maintenance systems can identify developing issues early, allowing for planned maintenance that costs a fraction of emergency repairs.

Component longevity is significantly improved through optimal maintenance timing and procedures guided by smart systems. Proper maintenance performed at the right intervals can extend component life by 50-100% or more, representing substantial savings over the lifetime of a bike. The precision of smart maintenance systems ensures that components receive exactly the care they need without over-maintenance that can also reduce lifespan.

For bike shops and commercial operations, smart maintenance systems provide substantial efficiency gains that translate directly to improved profitability. Automated diagnostic systems reduce the time required for problem identification, while smart tools and systems streamline repair procedures. These efficiency improvements allow shops to serve more customers with higher quality service while reducing labor costs.

The improved customer satisfaction resulting from more reliable bikes and better maintenance service creates additional value through repeat business, referrals, and premium pricing opportunities. Customers who experience the benefits of smart maintenance are often willing to pay premium prices for superior service and are more likely to return for future maintenance needs.

Integration with Existing Bike Shop Operations

The successful implementation of smart maintenance technology requires careful integration with existing bike shop workflows and systems. The most effective approaches involve gradual adoption that allows staff to become familiar with new technologies while maintaining service quality and customer satisfaction during the transition period.

Training and education are crucial components of successful smart maintenance integration. Shop staff must understand not only how to operate new equipment but also how to interpret diagnostic data, communicate findings to customers, and integrate smart maintenance recommendations with traditional mechanical expertise. This training investment is essential for realizing the full benefits of smart maintenance technology.

The integration of smart maintenance systems with existing point-of-sale and customer management systems creates comprehensive service records that enhance customer relationships and improve service quality. Detailed maintenance histories, predictive maintenance schedules, and automated follow-up communications help shops provide superior customer service while building long-term relationships.

Workflow optimization is essential for maximizing the benefits of smart maintenance technology. Shops must redesign their service processes to take advantage of automated diagnostics, predictive maintenance capabilities, and improved efficiency provided by smart tools. This optimization often involves restructuring work areas, adjusting staffing patterns, and developing new service packages that highlight the benefits of smart maintenance.

Customer education and communication are vital for successful smart maintenance adoption. Customers must understand the benefits of predictive maintenance, the value of regular monitoring, and the long-term cost savings provided by smart maintenance systems. Effective communication helps customers appreciate the value of premium maintenance services and encourages adoption of maintenance plans and monitoring systems.

Environmental Impact and Sustainability

Smart maintenance technology contributes significantly to environmental sustainability through improved resource efficiency, reduced waste, and extended product lifecycles. These environmental benefits align with the growing emphasis on sustainable transportation and responsible consumption in the cycling community.

The precision of smart maintenance systems reduces waste by ensuring that components are replaced only when necessary and that maintenance procedures use optimal amounts of lubricants, cleaning agents, and other consumables. Traditional maintenance often involves over-application of products or premature component replacement due to uncertainty about actual condition, resulting in unnecessary waste.

Extended component lifecycles achieved through optimal maintenance timing and procedures reduce the environmental impact associated with manufacturing, transportation, and disposal of bike parts. When components last 50-100% longer due to proper maintenance, the environmental footprint per mile of cycling is significantly reduced.

Automated cleaning systems typically use less water and cleaning agents than manual washing while achieving superior results. The precision control of these systems eliminates waste while ensuring thorough cleaning, contributing to both environmental sustainability and cost savings.

The reduction in emergency repairs and component failures achieved through predictive maintenance eliminates the environmental impact associated with expedited shipping, emergency manufacturing, and disposal of prematurely failed components. This prevention-focused approach aligns with broader sustainability principles of reducing consumption and waste.

Future Developments and Emerging Technologies

The smart maintenance revolution is still in its early stages, with numerous emerging technologies poised to further transform bike care in the coming years. Artificial intelligence capabilities continue to advance rapidly, with new machine learning models providing increasingly sophisticated diagnostic and predictive capabilities.

The integration of blockchain technology with maintenance systems promises to create immutable service records that can follow bikes throughout their lifecycles, providing valuable information for resale, warranty claims, and maintenance optimization. This technology could revolutionize the used bike market by providing verified maintenance histories and component condition data.

Advanced materials and nanotechnology are enabling the development of self-monitoring components that can report their own condition and maintenance needs. These smart components could eliminate the need for external sensors while providing even more detailed and accurate condition monitoring.

The development of fully autonomous maintenance robots represents the ultimate evolution of automated bike care. These systems could perform complete maintenance procedures with minimal human intervention, making professional-level bike care available 24/7 and further reducing the barriers to optimal bike maintenance.

Virtual and augmented reality technologies are being integrated with maintenance systems to provide immersive training experiences and real-time guidance for complex maintenance procedures. These technologies could make advanced maintenance techniques accessible to cyclists with limited mechanical experience while improving the efficiency and accuracy of professional mechanics.

Conclusion

The smart bike maintenance revolution represents a fundamental transformation in how we care for our bicycles, offering unprecedented levels of precision, efficiency, and accessibility. The integration of AI-powered diagnostics, automated cleaning systems, IoT sensors, and intelligent mobile applications is democratizing professional-level bike care while reducing costs, improving safety, and extending equipment lifecycles.

As we’ve explored throughout this comprehensive analysis, the benefits of smart maintenance technology extend far beyond simple convenience. These systems are creating a more sustainable, efficient, and enjoyable cycling experience by eliminating many of the traditional barriers to proper bike care. The predictive capabilities of modern systems prevent problems before they occur, while automated tools make maintenance tasks faster and more consistent than ever before.

The continued evolution of smart maintenance technology promises even greater advances in the coming years, with emerging technologies like blockchain integration, autonomous maintenance robots, and self-monitoring components poised to further revolutionize bike care. As these technologies mature and become more accessible, they will continue to transform the cycling experience for riders of all levels.

For cyclists considering adoption of smart maintenance technology, the investment represents not just an upgrade in maintenance capabilities but a fundamental improvement in the cycling experience. The combination of improved reliability, reduced costs, and enhanced performance makes smart maintenance systems an increasingly compelling choice for serious cyclists and casual riders alike.

The smart maintenance revolution is ultimately about empowering cyclists to get the most from their bikes while minimizing the time, effort, and expertise required for proper care. As these technologies continue to evolve and improve, they will play an increasingly important role in making cycling more accessible, enjoyable, and sustainable for riders around the world.

For more insights on cycling and technology, explore our comprehensive guides on Tech Tips for Modern Cyclists, Cycling Training Optimization Strategies, iBike NEWTON Power Meter Integration, Isaac Ride Analysis and Performance Tracking, and Bike Hacks for Enhanced Performance.

Explore additional resources on Bicycle Retailer & Industry News, Cycling Weekly – Best Budget Smart Trainers and Maintenance Tools, Remco Tools – Electric Height Adjustable Bicycle Repair Stand Innovation, Velobrush – High-Tech Bike Washing Machine Technology, and Final One AI – The Next Evolution in Bike Maintenance.